Transformer and Controller Retrofit for Utility Plant in Indonesia

Application

Industry: Power

Capacity: 2 units x 300 Megawatts

ESP OEM / Information: Zhejiang Sunyard

Process: Power Boiler

Country: Banten, Indonesia

Problem

The plant experienced Transformer Rectifier (T/R) set problem that caused some ESP fields (Unit 1; field 3A1 and 4A1) not operating. They planned to replace a new T/R set in order to have the ESP fields back to running. However, during initial data check on the existing Chinese T/R sets, Tai & Chyun found no data available for feedback signal resistor and voltage divider, which are crucial to the manufacture of T/R set. There was also discrepancy between the readings from analog meters and controller displays.

Solution

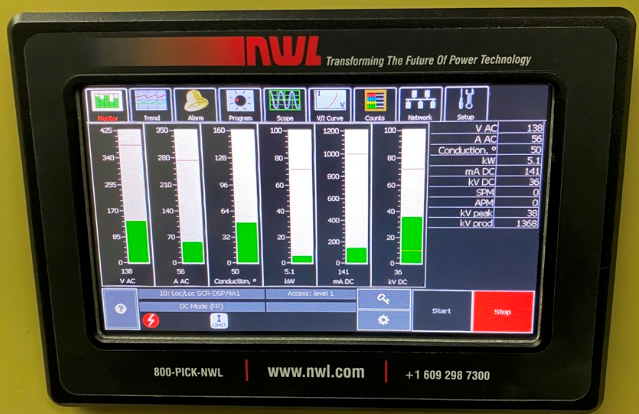

Tai & Chyun started with inquiring about the problem in detail and understanding customer’s expectation of having a T/R set with better quality. Through analysis of the existing T/R set data, we suggested retrofitting both T/R set and controller. This method would help customer ease their future maintenance work by employing more reliable equipment. Complete drawings, parameters’ setting information, supervision of installation and commissioning were provided. Furthermore, we offered onsite training to educate end-users about technical and operation procedures as well as key features of our T/R set and new Graphic Voltage Control (GVC) controller.

Benefit

Since the old T/R sets and controllers were out of commission (OFF) before retrofit, no data was recorded. Once retrofit had been completed, we recorded the load test (commissioning) data performed in January 2020 as shown in Table 1. A request was made to the plant not to increase the values of both kV and mA during load test since the condition of boiler was not yet stable.

Table 1 Load Test of Field 3A1 and 4A1

| Field | V AC | An AC | Duty% | kW | mA DC | kV DC | SPM | APM |

| 3A1 | 134 | 55 | 49 | 4.5 | 128 | 35 | 0 | 0 |

| 4A1 | 138 | 56 | 50 | 5.1 | 141 | 36 | 0 | 0 |

Positive feedback about the newly installed T/R sets and GVC controllers was evident. The performance of T/R sets were stable and efficient, where their ratings could be adjusted and monitored according to operation requirement through GVC controllers. The ESP running data after installation could be observed in Table 2 with satisfactory results.

Table 2 Updated ESP Running Data of Field 3A1 and 4A1

| Field | Before Retrofit | Data Collection Date | kV | mA |

| 3A1 | OFF | 13 April 2020 | 45 | 213 |

| 4A1 | OFF | 31 March 2020 | 49 | 411 |

*Field 3A1 mA rating was limited to 30% while Field 4A1 mA rating was limited to 40%

In addition, GVC controller not only features user-friendly interface that allows users to access all the important operating data of ESP in various forms such as VI curve, bar graph, trend plot, etc. but also enables direct data monitoring from the screen in order to detect any ESP problems promptly with complete troubleshooting information.

Old controller

Old T/R set

New GVC controller

New T/R set