Ash Handling System Installation for Power Plant

Application

Industry: Power

Production Capacity: 4 x 65MW

Ash Capacity: 4 ton/hour

Problem

The plant was using a Dilute-Phase ash handling system with transferal air force from the blower. Carbon-steel pipes were being used as ash conveyor elbow pipes, which usually caused leakage and clog. Moreover, there was only one pipeline for transferring ash in series to the silo.

Therefore, the plant consulted with Tai & Chyun for the best suggestion. With only one pipeline available to transfer ash to the silo, the entire ash handling system would be jeopardized should there be any blockage or clog in one or more of the conveyor pipes.

Solution

Tai & Chyun proposed a new ash handling system replacement with Dense-Phase and top-discharge. Transferal air force comes from the compressor, which allows the ash conveyor pipes to be made smaller to save more space. Elbow pipes are made of ceramic sleeves for longer life span. New design has been applied with 2 blow tanks per pipeline that can be operated independently from the other set of pipeline for transferring ash to the silo that eases operation and reduces risks.

| Old System | New System | |

| System | Dilute-Phase | Dense-Phase |

| Design | Bottom-discharge | Top-discharge |

| Pipeline | 4 Blow tanks, 1 pipeline | 4 Blow tanks, 2 pipelines |

| Pipe | Carbon-steel | Ceramic sleeve on elbow |

| Valve | Bell valve | Inlet: Rotating Disc Valve

Outlet: Rotating Double Disc Valve |

Comparison between the old and new system

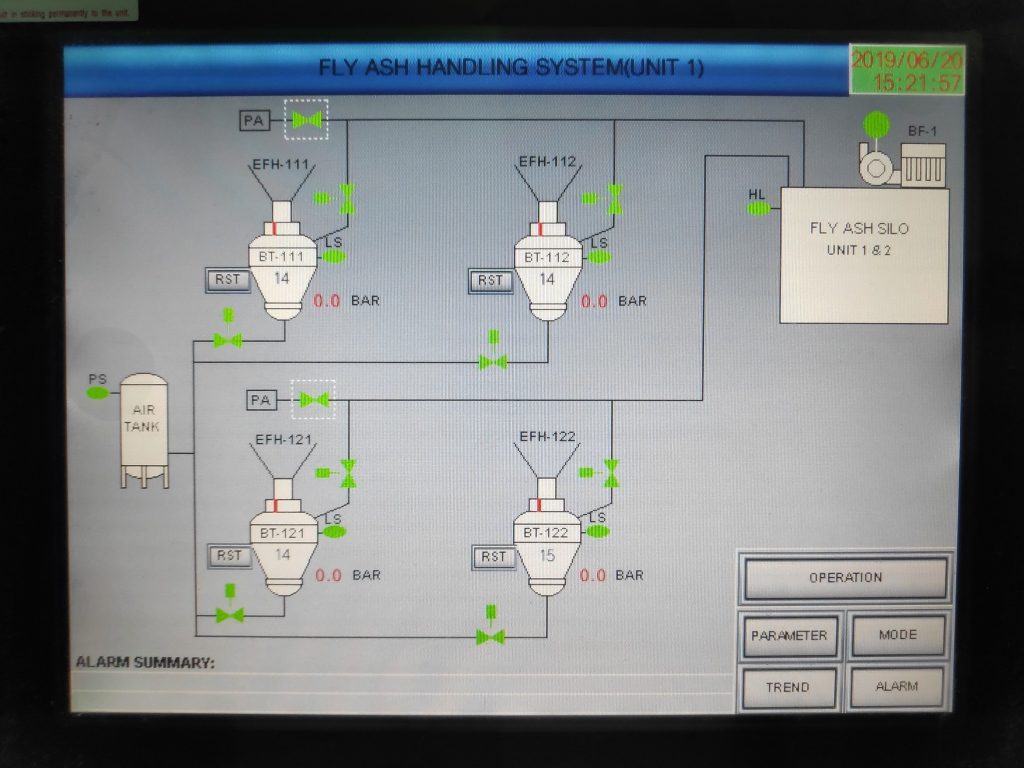

PLC & HMI programs have also been installed to provide functions for monitoring ash transferal where timer and pressure for each blow tank can be adjusted through different settings. A “disable” function is also available for disabling the blow tank in case one of them is faulty while the others are still able to continue operating transferring ash.

Benefit

Dense-phase pneumatic system can be described as ash transferal to ash silo at the lowest velocity with more ash to air ratio. It is simple and efficient in transferring ash that causes minimal abrasive force to the pipeline, thus pipes used are smaller compared to Dilute-phase pneumatic system. The purpose of using ceramic elbow and straight pipe is to reduce abrasion and turbulence in the pipeline.

New design of the ash handling system per unit of ESP is 4 blow tanks for 2 pipelines. Any blow tank can be disabled independently for necessary maintenance while the others still operate normally.

Tai & Chyun’s design adopts Rotating Disc Valve for inlet valve and Rotating Double Disc Valve for outlet valve. Both types of valves are sealed with tungsten ring of excellent mechanical properties and wear-resistant as well as hardness level up to 90HRC. Our design solves the issue of short life span resulting from surface abrasion and erosion.

On top of the silo, cartridge bags are used as bag filter with more filter area but less amount of bags. The function of a bag filter is to release the air pressure from ash being transferred from the blow tank inside the ash silo.

With regards to the new PLC with HMI display for ash handling system, HMI display is able to show the ash count being transferred, the opening and closing of valves, and the level of pressure inside the blow tank. Not only settings of parameters and modes for ash handling system can be done directly in HMI, but its alarm can also show error warnings within the ash handling system if any.