Application

ESP for Power Boiler No.5 of a Pulp and Paper Company in Thailand.

Problem

This ESP contains 3 fields dry precipitator and has continually been in operation since 1997. Accordingly, they would like to upgrade the power boiler capacity from 138 TPH to be 198 TPH, in which originally this boiler was designed for the optimal capacity at 200 TPH.

Tai & Chyun helped the customer to analyze and calculate an efficiency of existing ESP for dust loading with new power boiler capacity in order to provide the best and economical solution for them.

Solution

Tai & Chyun recommended that only mechanical refurbishment inside the ESP is required to keep their ESP operating efficiently. Tai & Chyun was awarded the contract to supply parts and installation job. With regard to this, customer agreed to refurbish the 2nd and 3rd field.

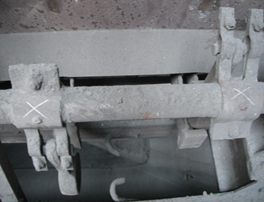

With this, Tai & Chyun supplied them CP, DE, and DE frame with new design since this ESP is quite old already. Therefore, their old design of DE and CP was already obsolete and unavailable in the market. Apart from that, we also help them to replace new GD screen and renew rapping system.

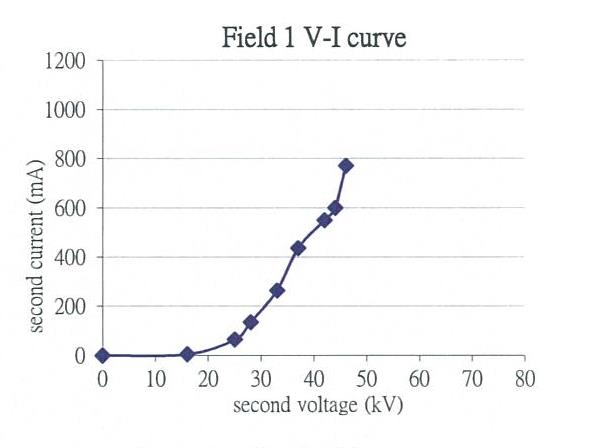

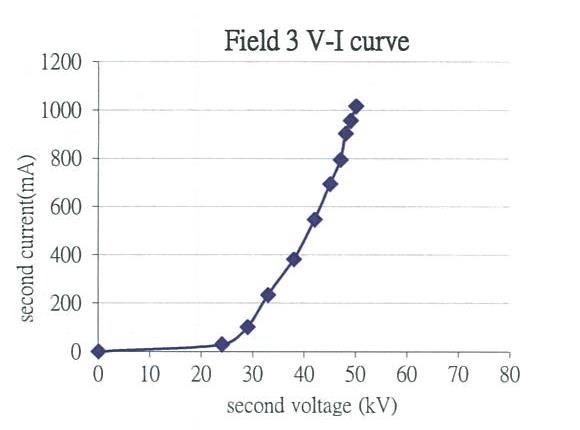

Accordingly, the result of the no load test shows that the operational data of the 2nd and 3rd field that Tai & Chyun did refurbishment is better than the 1st field proving its enhancement and there is no report of emission after all.