Valve Leakage (Valve Passing) in Fly Ash Handling System

Valves are used to start or stop the ash flow in a conveying line. Inlet valves and discharge valves are constantly in contact with ash, and thus are inevitably prone to abrasive and erosive wear. Erosive wear happens during blow tank pressurizing stage, when fly ash is fluidized with high pressure air. The ash-air flow erodes the location which already leaks from abrasion. Erosive wear accelerates the disc wear and it is the major cause for valve leakage (valve passing). Valve leakage can lead to decrease in system throughput, in worst case, pipeline clogging. The different valves available in the market can be generally divided into soft seal and hard seal types.

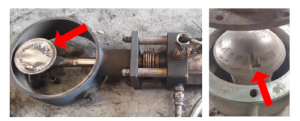

Erosion of Valve Disc

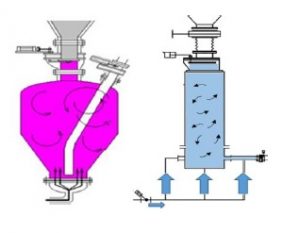

Soft Seal Valve

One of the two sides of sealing pair is made of metal and the other is flexible non-metallic materials. Soft seal valve has good sealing quality but poor erosive resistance. The most commonly seen soft seal valves are dome valves and flap dampers. Under normal operation conditions, the seals usually last one to three months. Preventive replacement of the valve seals and constant monitoring of pressure build-up time during pressurizing stage are recommended to avoid early failure of valves.

Flap Damper Valve seal

Dome Valve seal

Hard Seal Valve

Both two sides of sealing pair are made of wear-resistant metal materials or other materials having high hardness, such as ceramic or tungsten alloy. Hard seal valves usually do not seal as perfectly as soft seal valves do, but they can endure high temperature and have better erosive resistance. The most commonly seen hard seal valves are double disc valves and rotating double disc valves. The bottom of the disc is supported by spring against the seat ring so to ensure good sealing and automatic compensation for wear.

Rotating Disc Valve

Double Disc Valve

Suitable Valve for Abrasive Fly Ash

Choosing a suitable valve is crucial for smooth system operation and minimum system down time. The life cycle of a valve is dependent on its application and frequency of use. Fly ash is highly abrasive material and application in ash conveying system often indicates high operation frequency up to 70,000 times per year.

For discharge valves, it also means operating with pressure differential across the valve at 0~4 bars or higher. In the purchasing strategy of most plants, although part cost is the major concern, cost of man power for repair and system down time during a valve failure should also be taken into account. With this in mind, Rotating Disc Valve is the ultimate choice for the ash handling system with its high reliability and cost-effectiveness.

Soft Seal Valve vs. Hard Seal Valve

| Dome Valve | Flap Damper | Rotating Disc Valve | Double Disc Valve | |

| Seal Type | Soft seal: Viton | Hard seal:

Ceramic or Tungsten Alloy |

||

| Drive Shaft | Protected in shaft housing | In contact with ash | ||

| Maintenance Frequency* | High

(1~3 months) |

Low

(1~2 years) |

Low

(2~3 years) |

High (1~3 weeks) Replace gland packing |

| Control Complexity | High (extra control for inflating seal) |

Low | ||

| Operation Temperature | 250℃

high temp. type: water cooling needed |

250 ℃ | 250 ℃: Standard type 350 ℃: High temperature type |

|

| Space Limitations | > 205 mm | > 750 mm | > 205 mm | > 205 mm |

| Particle size | Powder & Granules | Powder | Powder & Granules (Limestone, Sand, Fly Ash…) |

|

| Price | High | Medium | Medium | Low |

*In the case of processing fine fly ash from bag house or ESP, installed at inlet of an ash transmitter,

at the operation frequency of 8 cycles/hour.