If there is a crack and/or hole on CP, it will be repaired by using dummy plate to weld on CP. If there is a bent CP, it could be adjusted manually by using special tools and/or heating. Nevertheless, it is very difficult to expect the perfect results from repairing; especially, if the length of CP is ≥10 meter.

However, results after repairing the broken CP will show some improvement on kV and mA value (~10-20%), but the performance improvement will not be as significant as comparing with replacing with the new CP.

RDE Installation

The invention of RDE is to help improve the performance of the existing DE, which can help leading ESP to better operating efficiency because RDE can generate higher aggressive current and overcome the below drawbacks from each type of DE.

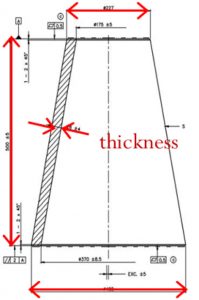

The quality of steel material is important since better quality will provide better durability and mechanical properties. Tai & Chyun always emphasize on the product quality. Accordingly, we can provide material test certificate such as chemical composition of the steel in order to ensure customer about the quality of the steel used.

Broken CP

Dust Build Up CP

Deformed CP

The reasons of CP failure are as follows:

Air leakage will make it easy for CP to be corroded from the moisture that occurs. Therefore, it causes sticky dust that can lead to dust build up problem on CP.

Severe hopper full up until reaching the rapping bar

Bent rapping bar

Detached CP interlock

High temperature due to process Issue

Poor product quality

Incorrect erection installation

Incorrect packing, transportation and loading

The tolerance level of dust accumulation on CP surface should be maintained in the range of 0.8 to 12.7 mm. If it exceeds that level, it will be categorized as dust build-up problem.

The thickness of dust layer affects the strength of the electrical field. For instance, it will lead to heavy sparking, thus suppressing voltage and current.

As a result, the kV and mA values will exhibit the low number followed by high sparking. Therefore, replacement of CP is necessary to provide better ESP performance.

It depends on how much percentage of missing CP. If the quantity of missing CP is more than 10% from the total amount of CP in each field, it will affect ESP condition and performance, causing high outlet emission. Therefore, CP replacement is expected to be implemented urgently. In case that missing CPs cause a huge decreases in ESP collecting efficiency, new CP then should be replaced immediately.

In the meantime, it will be better to control the ESP process and operating data such as the temperature control, uniform gas distribution, and maintaining kV and mA in proper value. Moreover, others ESP parts such as DE, CP rapping system, DE rapping system, insulator, etc. must be kept in the good working condition. Regularly checking and maintenance is always necessary to be aware of ESP condition is in the suitable tolerance or not.

The cycle time depends on the following factors:

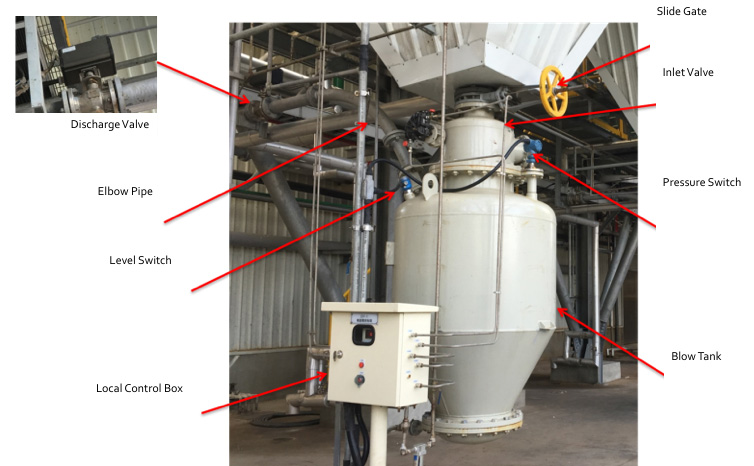

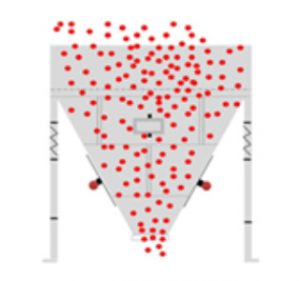

Components of Ash Handling System

Due to centrifugal force and inertia, when the fly ashes are delivered through the elbow pipe, it impacts the wall outer elbow. It causes the friction that leads to wear and broken elbow pipe. As a result, elbow pipe will become leakage.

Therefore, the elbow’s wearing problem has become the primary consideration for pneumatic conveying system, while the wear problem of the straight pipe is much smaller.

Recommendation:

The maximum conveying distance is at 1500 meters with vertical lifts of 50 meters.

The maximum conveyor line pressure is 0.4 Mpa (4kg/cm2).

The maximum conveying capacity for DEPAC is 250 TPH.

A top discharge would be the most appropriate to use where there is a fine particle such as fly ash. A bottom discharge would be appropriate where there is coarse material or material that does not fluidize well.

DEPAC System

Yes, it is. However, the slide gate valve must be closed between the ESP hopper and transmitter.

1. Close the slide gate valve between the hopper and transmitter

2. Change over to “LOCAL” the operation mode selector switch on the local control panel

3. Pressure Gauge: Check operation pressure

4. Slide Gate Valve: Check leakage from gland

5. Inlet Valve: Check smooth action

6. Air Inlet Valve: Check smooth action and leakage from flange

7. Transmitter: Check operation cycle

Yes. It is possible to perform ESP water washing. ESP water washing has both advantages and disadvantages as listed below

Advantages

Disadvantages

Before ESP Water Washing

Preparation of ESP Water Washing

Performing ESP Water Washing

After ESP Water Washing

Water washing can generally be performed in various type of ESP. Tai & Chyun has experiences in performing water washing for ESP from different industries including petrochemical, power, glass, etc. However, we do not recommend ESP water washing for the type of ash which is acid or causticity.

Buffet Pool

Bags for collecting wet dust

ESP Water Washing

It is strongly suggested to do inspection for the overall ESP parts, starting from the electrical parts such as transformer (terminal box, insulation testing, V-I curve, T/R set appearance), insulators, heaters, rapping motors, controller, and rapping testing, followed by mechanical parts for both external and internal ESP. For external part, it could start from the casing including cladding and insulation, access door and manholes. It might be having problems with leakage or deteriorated gasket seal. Then, we could inspect the expansion joint, inlet, and outlet nozzle. ESP structure is also necessary to be checked. For internal part, the order could be listed as below:

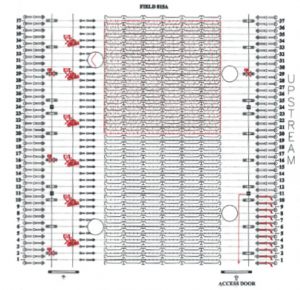

ESP Inspection Chart

ESP Inspection

Yes, it is possible. From the first time, we can do the V-I curve testing by comparing the graph from inlet to the outlet field to evaluate and maintain ESP condition over period of time. Deviation from the normal or previous result can indicate that there are some ESP problems happening. Primary readings should be proportional to the secondary reading. If not, it should be expected that the problem may come from electrical.

Performing ESP inspection during shutdown is necessary as part of ESP routine maintenance and performance monitoring, leading to a good ESP operation. ESP Inspection includes testing, measurement of ESP parameter, comparison of the parameters with the original design condition/ value, and keeping record of ESP performance. Accordingly, these data is useful for ESP performance evaluation and problem diagnosis. An analysis of the key parameter can help to identify many ESP problems; indicating the need for maintenance and/or replacing part with the new one.

Electrical shock:

Uneven loading and misalignment:

Exceeding the maximum voltage or temperature:

Most of the support insulators are made from alumina-oxide porcelain, in which it usually contains 50 % of alumina content and is typically made with glazed surface in order to reduce the deposits of dirt and dust.

Other materials of support insulator such as fiber glass or Teflon may not be suitable enough because of its poor thermal resistance and fragility.

Easily crack or break

Easily cause sparks in ESP

You need to inform sales representative about the following details.

Removing the original controller and SCR

For more product detail and the installation preparation, please feel free to consult with our technical team at any time for your PowerPlus inquiry.

In general, it should be installed on ESP roof to lower the impedance between ESP and PowerPlus. Since PowerPlus operates in high frequency, it could react faster than conventional 60Hz T/R set. However, to install Powerplus on the ground is also feasible by requiring specific type of cable, together with some cable modification, but it has some distance limit in order to avoid the noise problem.

In order to avoid over temperature problem, an ambient temperature must be kept not to exceed 45°C, while the PowerPlus has developed the function of temperature control to decrease the power automatically when the temperature is over 62°C in order to prevent the trip problem. However, it is recommended that heat exchanger fin should be cleaned regularly when performing PowerPlus maintenance to allow for an effective temperature control.

The distance between CP and CP or DE and DE can be varied from 250 – 450 mm. The old design uses 250mm, the common design usually uses 300 – 400 mm and the newest design tries to use 450mm.

If the close gap was caused by bending, detached or broken CPs or DEs, those CPs and DEs should be removed to prevent ESP trip. However, the allowed quantity for CPs or DEs to be removed is 10 % of total quantity in each field. If there are more than 10% that are damaged, the whole field replacement is needed to be considered.

There is no ideal distance between CP and DE for the repair works as long as the safety provisions can be met and the worker is able to fit and execute the repairing job safely. However, if the access is not possible, it should be discussed among the maintenance team and safety staff for considering about access modifications.

If CP and DE deforms, of course it will cause close clearance between CP and DE. In case that deformed CP or DE cause some serious disturbance to the ESP performance, it will be better to remove the deformed CP or DE out in order to prevent problem about close clearance between CP and DE. Water spray can also help to reduce the operating temperature to prevent the problem about CP and DE deformation. Apart from that, it is also necessary for the plant personnel to regularly address all the leakages inside ESP in order to prevent the moisture getting inside ESP to cause some corrosion as well as deformation.

Close Clearance between CP &DE

Deformed DE

Good Alignment between CP & DE

Dust Build Up CP

Damaged Boot Seal

Water Leakage

Misaligned Rapper

Corroded Terminal

Mechanical

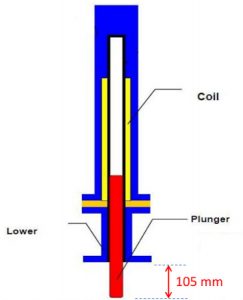

Checking the space between the bottom of plunger and bottom of MIGI Rapper:

Electrical

Checking the current when operating

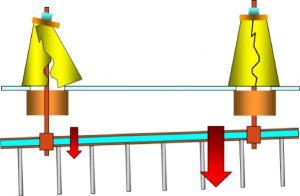

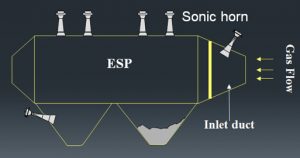

Yes, sonic horns are installed as supplementary equipment for dislodging the dust in order to help enhance dust collecting efficiency. It is functioned to help dislodge an excessive level of dust by using sound vibration to fluidize dust build-up inside ESP. Once the dust particle absorbs the sonic energy and vibrates, the adhesion force of the dust will be weaken to be collected easily. Mostly sonic horns are founded to be installed at the following location

On the roof: to help dislodging dust on CE inside ESP

On the hopper: to help preventing the dust-build up in the hopper due to bridging or rate holing problems

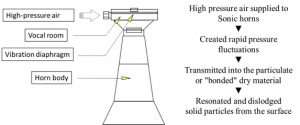

Sonic horns use powerful sonic sound waves operating at frequencies between 60Hz to125 Hz and 140~150dB to dislodge the collected ash.

The way for sonic horn to produce the sound waves is illustrated as below:

|

Item |

Description |

Compare to Sonic horns |

|

|

Air cannon |

A compressed air device to dislodge powdery material |

|

|

|

Hopper Vibrator |

Apply vibration to dust pile |

|

|

Sonic horn can be applied in any area where there is the dust that needed to be dislodged such as in bag house, economizer, silo, induced drag fan or heat exchanger, etc. You can consult for more detail with our sales representative for any specific location to suite with your requirement to help solve your dust build up problem.