Application

High Frequency Transformer and Controller System Upgrade in an Oil Refinery in Taiwan.

Problem

- Emission test is not satisfactory at 30~50 mg/Nm3.

- The TR set oil is not available anymore and substitute fluid is difficult to find locally and using substitute is risky.

- The ESP controllers have been in use for 12 years raising concerns on spare parts obsolescence, control reliability and their effect on ESP efficiency.

Solution

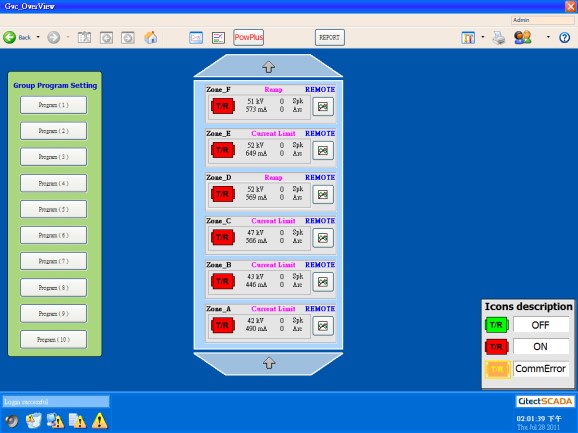

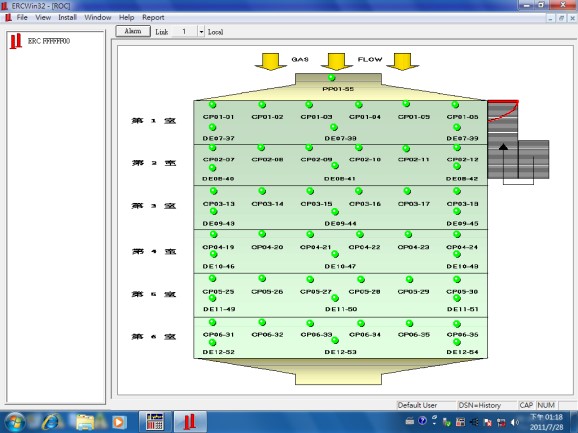

- 6 sets of Conventional T/R Sets are all changed to 6 sets of High Frequency T/R Sets. 6 sets of Keypad Displays are also installed for controlling from local control room.

An ESP overall SCADA system is installed in center control room.

Benefits

1. Difference in Output kW

Originally, the first three chamber’s (at the ESP’s inlet side) T/R Set output was 12.5 kW, and the last three chambers’ output was 25 kW. The Powerplus supplied was rated at 56 kW in total.

From the following table, it is seen that the output of the first three chambers increased approximately 4 times, and the last three chambers increased approximately 1.5 times, total power increased by approximately 250%

| Zone | A | B | C | D | E | F | Total |

| T/R Output Rate(kW)- Before | 7.75 | 11 | 11.2 | 22.75 | 24.5 | 24.5 | 101.7 |

| T/R Output Rate(kW)- After | 38.5 | 44.8 | 44.8 | 43.2 | 43.2 | 38.4 | 252.9 |

| Percentage of Increase | 496 | 407 | 400 | 190 | 176 | 156 | 248 |

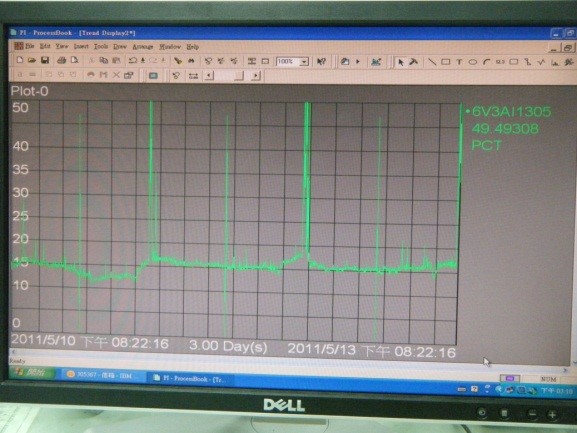

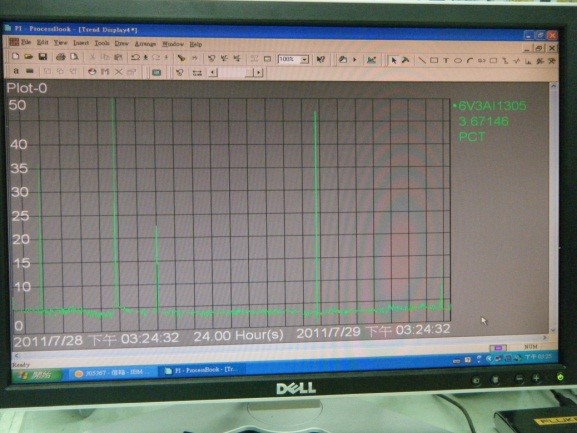

2. Comparison of Opacity

Before revamping: Opacity was around 14~16%

After revamping: Opacity became to 5~6%.

3. Dust Emission Summary

| Concentration | |

| Before Revamping (historical data) | 30~50mg/Nm3 |

| After Revamping | 11.9mg/Nm3 (Calibration of 10mg/Nm3) |

| Customer’s Acceptable Requirement | Below 15mg/Nm3 |