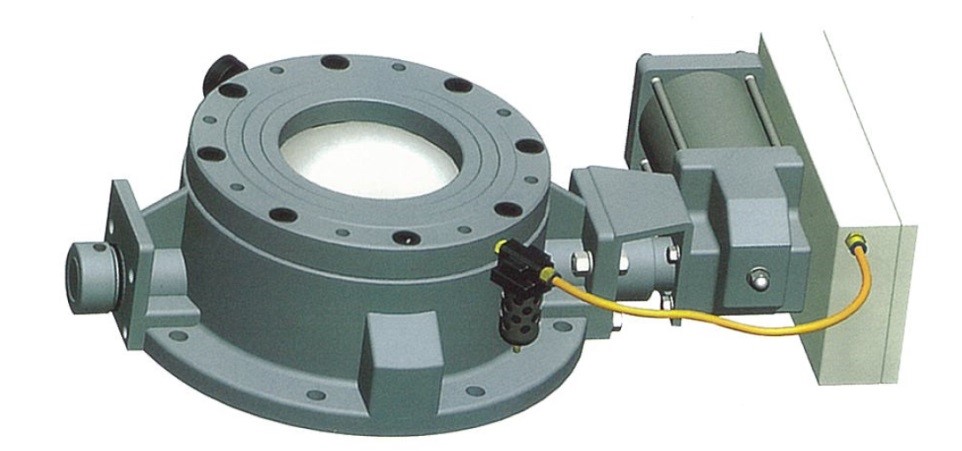

Charging Dome Valve

What is Charging Dome Valve?

Charging Dome Valve is a switch for conveying materials. It plays the role in opening and partitioning pipeline space.

Dome valve is a spherical dome. During the opening and closing process, a gap of 0.5~1.2mm is maintained between the valve core and rubber seal ring in order to allow for non-contact between the valve core and rubber seal ring. The purpose is to avoid friction between valve core and rubber seal ring; thereby, reducing the wear and tear problem. The dome valve’s pneumatic actuator is a 90 degrees rotary swing cylinder, in which the cylinder drives dome valve core through rotary shaft, while the valve is shut off by a spherical valve and charged rubber seal ring.

Where does Charging Dome Valve use at?

Charging Dome Valve is applicable for loose, dry, cohesive and mobile particulates within the sealed conveyor system; especially for the fly ash treatment system of the thermal power plant. It is widely installed in heavy industries including power, petrochemicals, cement, metal, etc. Charging Dome Valve is applicable for medium including gas, liquid, semiliquid and solid powder.

What is the material of Charging Dome Valve?

Depending on its application, different types of materials are used to produce dome valve core, and different types of hardening treatment are applied. However, good quality of Charging Dome Valve should have smooth and hard surface of the valve core to ensure close contact and reliable sealing with the rubber seal ring. The rubber seal ring is made of special rubber, which contains high resistance characteristic for high temperature, corrosion, wear, and aging resistant, leading to long service life.

Specification :

| Technical Parameters:

Nominal Pressure: 1.0 Mpa Medium Temperature: ≦180°C Strength Test: 1.5Mpa Sealing Test: 1.1 Mpa Pneumatic Actuator: 90 degrees Rotary Swing Cylinder |

| Size(mm) | Connection Dimension | |

| DN | Outer | Inner |

| 65 | 185 | 145 |

| 150 | 285 | 240 |

| 200 | 400 | 360 |

| 300 | 510 | 465 |

Tips for Installation and Operation:

- Do not open the valve before compressed air is not discharged! Do not allow water or wet particulates to enter into the valve.

- Do not weld the flange after the valve is installed. Failure to follow this instruction will cause damage to the rubber seal ring of the valve.

- Periodically check the working status of the dome valve; take corrective actions immediately when abnormal operation is encountered.

- Please follow safety operating procedure when lifting, installing, commissioning and repairing the valve.

- The valve is strictly tested and calibrated before it goes out of the factory; gas circuit has already been connected.

At Tai & Chyun, we provide products at reasonable price, on-time delivery, long service life and good after-sales service.