Rigid Discharge Electrode (RDE) and Switch Mode Power Supply Upgrade at Power Plant in Hong Kong

Application

Process: Power Boiler

ESP OEM: Lodge Sturtevant

ESP Specification: Quadruple-chambered

- 24 mechanical fields

- 18 electrical fields

Boiler Capacity: 677 MW

Country: Hong Kong

Problem

The ESP is quadruple-chambered with 6 mechanical fields in each chamber making a total of 24 mechanical fields. For every 2 chambers, there are 9 Transformer Rectifier (T/R) units (9 electrical fields) serve as power supply making a total of 18 electrical fields. With the boiler capacity of 677MW, the ESP was originally designed with non-rigid type Discharge Electrode (DE) and equipped with conventional power supply.

The ESP has been in operation for more than 30 years. Internally, small gaps (225mm) between Collecting Electrodes (CE) and aged mechanical parts had a huge negative impact on the ESP performance. Some mechanical fields tripped due to short circuit between CE and DE.

Although ESP outlet emission was in compliance with government regulations, the plant somehow expected to be able to employ a wider range of tolerance for coal types with different levels of ash content. Deteriorated internal parts also caused high opacity which in some cases could reach 40% during rapping time. In addition, RDE replacement during previous annual maintenance was carried out with the wrong method and thus resulted in bent RDE that worsened its emission.

Solution

ESP assessment had been recommended by doing thorough inspection and results suggested replacing RDE in certain fields (6 fields) and upgrading conventional power supply to Switch Mode Power Supply (SMPS) for all 18 electrical fields were appropriate choices. For such a huge work scope, the upgrade project must be guaranteed of emission reduction by at least 25%. The upgrade project had been completed within nearly 3 months, from March to May 2020.

The biggest challenge was the design part that required high accuracy as no further modification could be done on site during the execution of the project. The plant’s contractor strictly worked according to the contract and only planned scope of work. Any or small modification and additional job done on site would be charged at a very high price.

Newly installed RDE (top view)

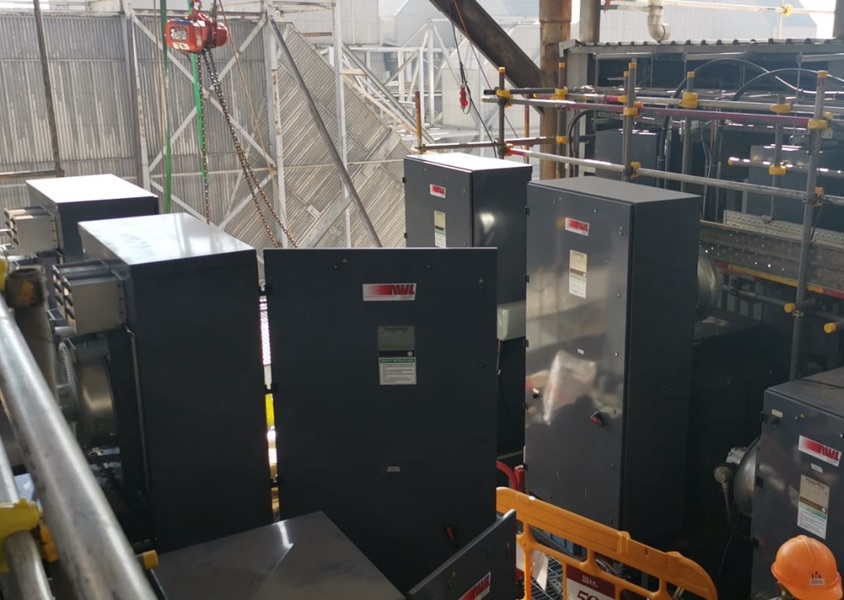

Installing new SMPS

Newly installed RDE (bottom view)

18 units of SMPS being installed

Benefit

By upgrading electrical and old auxiliary system from single phase to 3-phase, not only operation reliability is enhanced but also power factor, or so-called efficiency of the power supply. Furthermore, new user interface helps operators better control the operation of the ESP. Ethernet cable is replaced with fiber optic cable that provides faster and steadier communication signal.

New HV cable is installed to be compatible with the new output kV of SMPS. Rapping system is also integrated into SMPS control. Remote monitor computer is installed in CCR for easy monitoring. All running data such as kV, mA, alarm report and trend history can be monitored and retrieved at CCR.

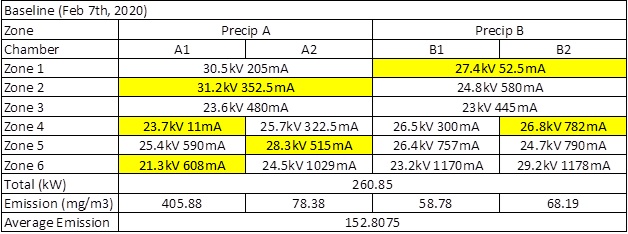

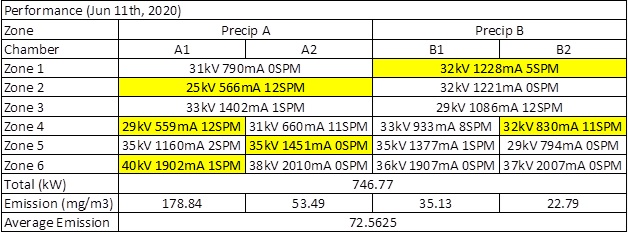

The performance test was both done before and after the upgrade. In February 2020 before the upgrade, emission was recorded at 152.81 mg/m3 at 520MW. In June 2020 after the upgrade, emission was recorded at 72.56 mg/m3 at 520MW.

| Before | After | % Reduction | |

| Emission | 152.81 mg/m3 | 72.56 mg/m3 | 52.52% |

The running data was also both recorded before and after the upgrade in February 2020 and June 2020. The upgrade generates more power to the ESP resulting in 186.28% increase in power output, thus increasing the dust collection efficiency of the ESP.

Running Data (Before)

Running Data (After)

Remark: Yellow highlights indicate fields that RDE replacement took place (total 6 fields)