Fly Ash Handling System Upgrade in Power Plant

Application

ESP of a Coal Fired Power Plant in Lampung, Indonesia.

Problem

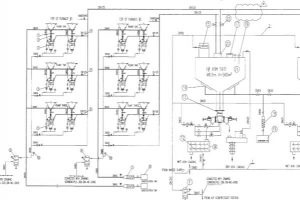

Previous system of t he fly ash handling was pneumatic dense phase with top discharge and its logic system of unit 1 and unit 2 had been integrated . Elbow pipe in ash hand ling transport system was pipe miter design carbon steel liner. Customer of ten experienced pipe leakage and blockage every 2-3 months . Pipe leakage cause s interfer ence t o the ESP fly ash transport process from hopper to ash silo. Due to the issue, customer had attempted to patch the leaking pipe with plate but to no avail.

Due to the fact that elbow pipe was miter design and made of carbon steel with huge radius of approximately 500 mm without inner ceramic liner , it was prone to leakage due to Flap damper that was used as inlet valve which user also often experience d bro ken rubber seal ring and double disc valve with ceramic seal as delivery valve also posed some problems . User had considered replacing ash silo unloader system since it was not working well with dry unloader as well as incompatible with wet unloader.

Above all, the main concern was the piping system connecting 6 hopper ash transporter tanks with only 1 pipe to transport ash to the silo. This layout possessed a high risk of dust clog and ESP must stop operation if it happens.

Solution

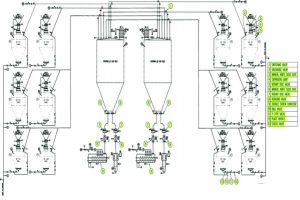

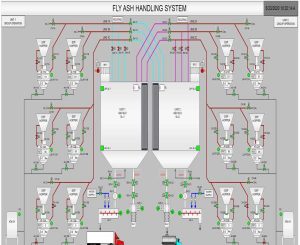

Tai & Chyun visited the plant to assess the problematic system and shared our experiences with other power plants that faced similar problems. We recommended modification and system upgrade for PLC program in order to meet user’s requirements. The modification included breaking down pipe layout from 1-line to 3-line connected to ash silo using Rotating Disc Valve (RDV) for inlet valve and Rotating Double Disc Valve (RDDV) for delivery valve (outlet valve). Furthermore, unloader system of ash silo has also been included in this replacement project to obtain better results.

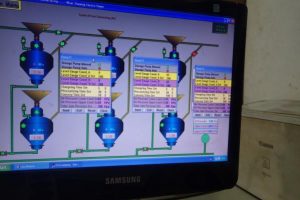

We were awarded with the project once user understood the benefits of the upgrade. Pipe layout has been redesigned in unit 1 and 2 ESP, both in the way that the 1st field consists of 2 pipes transferring ash to the silo from hopper 11A and 11B while the 2nd ~ 3rd field remains the same with 1 pipe line to the ash silo. Together with application of smooth ceramic-liner Y-type, Elbow and 500-mm radius Straight pipes provided by Tai & Chyun that give longer lifetime, logic system control has also been upgraded to enhance operation and make it easier for user to monitor and troubleshoot.

Benefit

Tai & Chyun’s ceramic pipes can extend the lifetime of ash transport system and at the same time solve the problems of leakage and blockage. Customer / user is also satisfied with the new upgraded logic system that provides easy operation control and monitoring, as well as prompt indication to problems for troubleshooting. The ceramic-liner pipes installed in unit 1 since August 2020 are still in good condition up until now and it has never been heard that the user has patched or done any maintenance on the pipes ever.

Picture

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

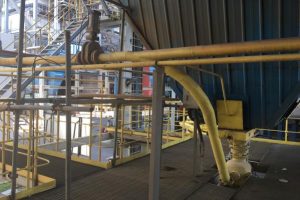

Before

After