Electrical Upgrade in Wet ESP

Application

Industry: Steel / Mining / Smelting

ESP OEM / Information: MHI – Wet ESP

Process: Detarer / Baking, Aluminum Smelting Plant

Country: North Sumatera, Indonesia

Problem

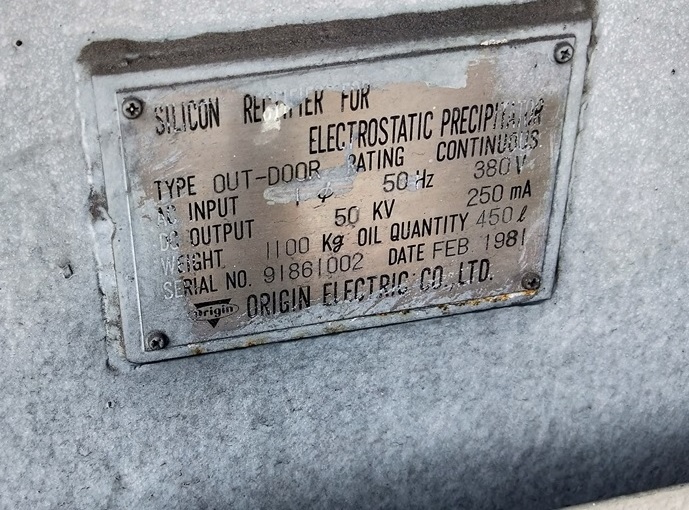

Original Transformer Rectifier (T/R) and controllers of the Wet ESP (aka Detarer) had been used for almost 40 years since 1981, therefore, their spare parts were obsolete and no longer available in the market. Moreover, the controllers were non user-friendly analog type and difficult for parameter setting adjustment. Customer had planned to renew the T/R and controllers of the Wet ESP along with its control panel.

Solution

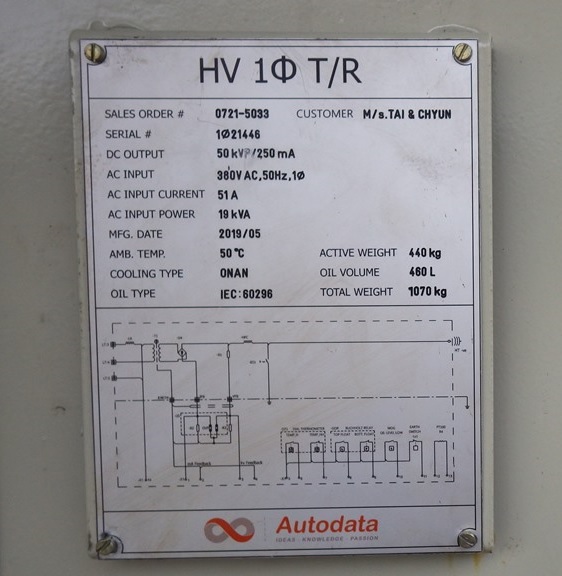

Wiring diagram, control panel specification and other necessary information related to original equipment had been collected and Tai & Chyun came up with an electrical retrofit proposal, which consists of T/R, Graphic Voltage Controller (GVC), Control Panel, and SCADA system. Since it was the first-time supply and once order had been awarded, Tai & Chyun assigned its engineers to customer site to confirm actual site condition and discuss further procedures with customer prior to project execution. Supervision, training, and commissioning were also provided as in the work scope.

Benefit

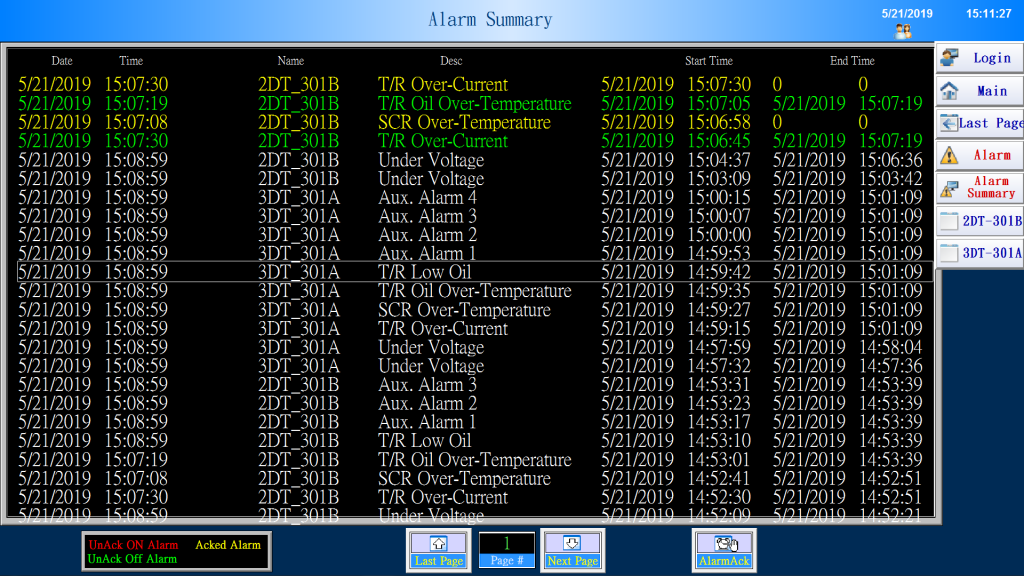

From commissioning until now, the new GVC, T/R, and SCADA system have been performing very well. SCADA system had been introduced into the retrofit plan in order to provide users with ease of monitoring and controlling the entire electrical system. Customer is satisfied with the result and planning to continue the upgrade on the other Wet ESP.

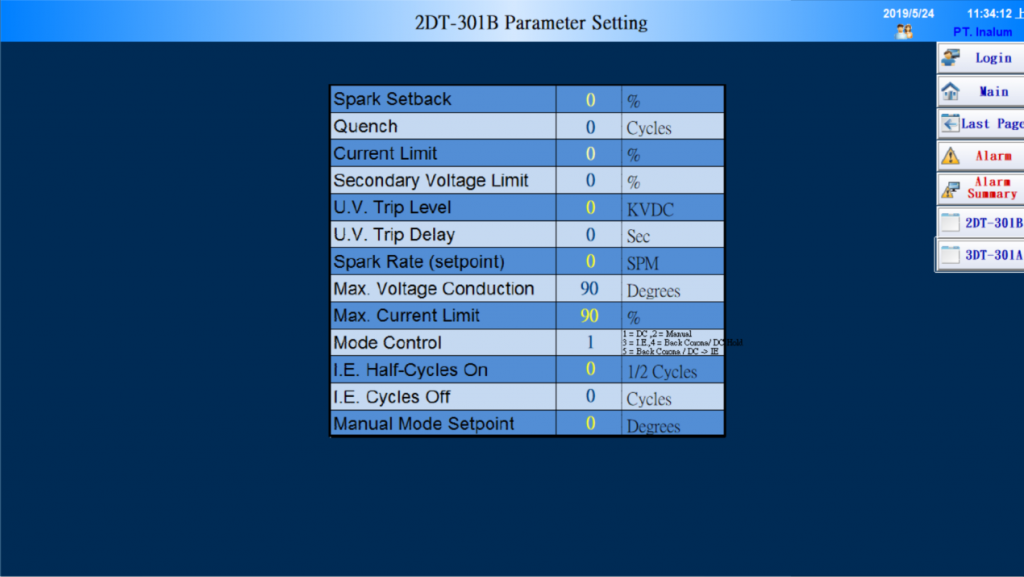

Following are some displays of SCADA system:

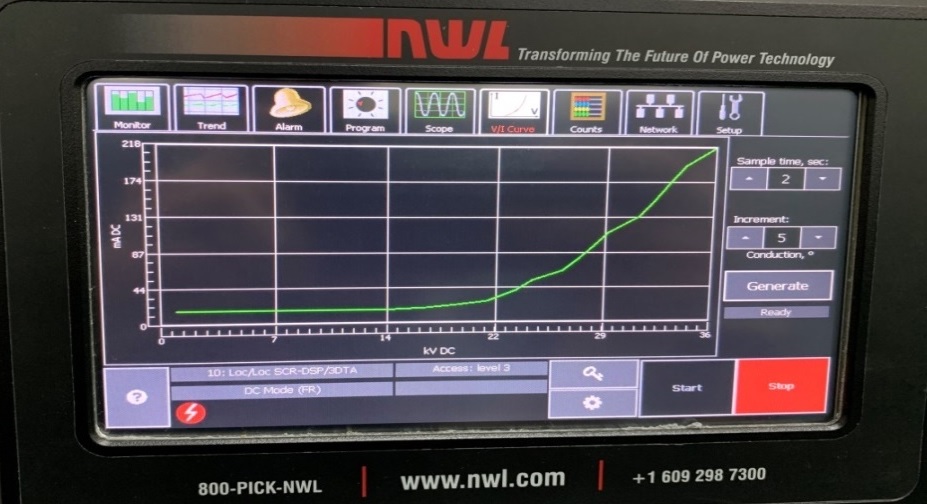

No-load test was performed during commissioning and both kV and mA were able to reach high values. The result of no-load test is shown below:

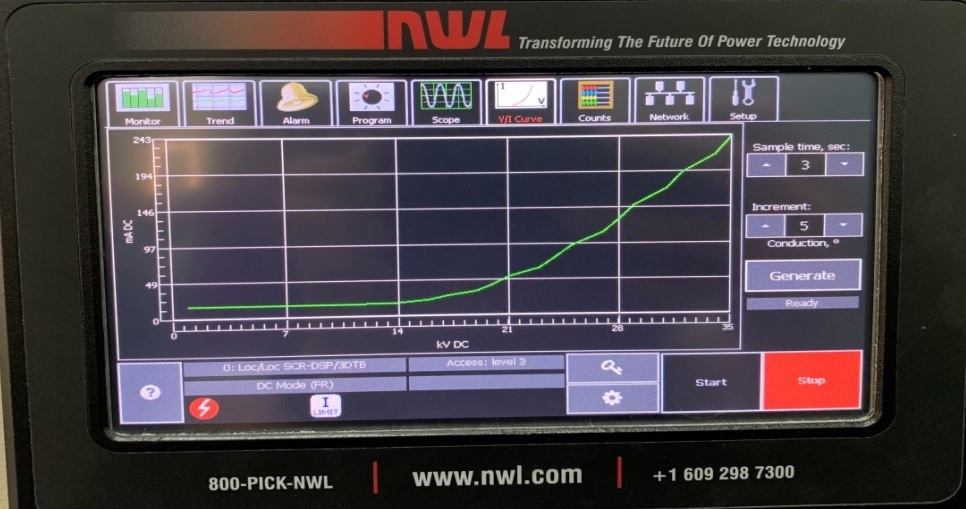

After commissioning, customer requested Tai & Chyun to adjust the limit setting of kV and mA values in order to comply with their plant’s requirement as photos shown below:

Below table shows kV and mA values at customer’s request:

| Field | Date | kV | mA |

| 301A | 29 August 2019 | 31 | 129 |

| 301B | 29 August 2019 | 29 | 163 |

Note: T/R Rating – 380V; 50Hz; 50kV; 250mA