Rigid Discharge Electrode Replacement in a Utility Plant

Application

Industry: Power

Capacity: 2 units x 150 Megawatts

ESP OEM / Information: KC Cottrell / 1 Chamber (5 Fields)

Country: Philippines

Problem

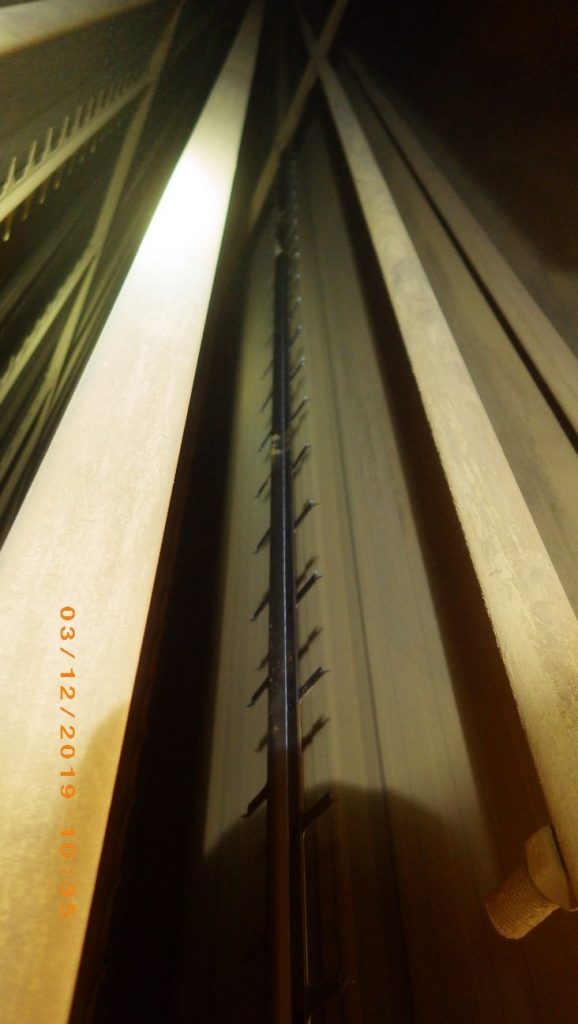

The ESP has been operating since 2015 and experiencing frequent trips due to short-circuit in each field that is caused by broken and cracked Discharge Electrode (DE). The existing DE was Chinese rigid type with 0.7 mm thickness, which easily cracks and eventually broke from the impact of rapping. The broken DEs came close and / or into contact with the Collecting Plates causing short-circuit.

Based on the last inspection in 2019, mid-broken discharge electrodes at the 1st, 3rd, and 5th fields that caused the trip were observed in Unit 1 ESP.

Cracked and broken Chinese DE

Solution

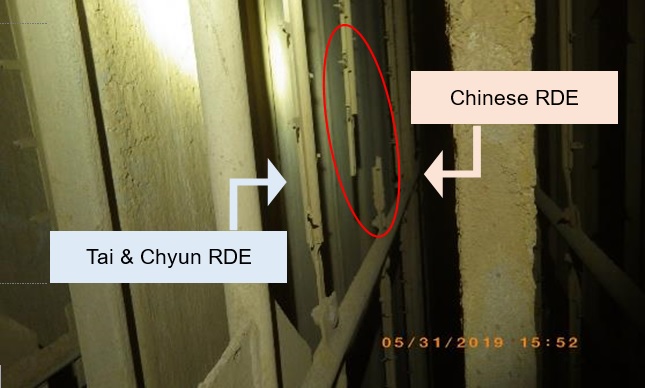

Tai & Chyun came up with a solution to help the plant increase the reliability of ESP during operation by recommending Tai & Chyun Rigid Discharge Electrode (RDE) with thickness of 1.2mm for direct replacement of the existing Chinese RDE. As of March 2020, a total of 2,638 pieces of Tai & Chyun RDE order was placed.

Benefit

After installation with Tai & Chyun RDE, each field operates at longer period of time without experiencing any short-circuit. With all fields working, the emission is kept at a very satisfactory level even below the target.

Photo

Existing Chinese Rigid Discharge Electrode

Newly Installed Tai & Chyun Rigid Discharge Electrode

Comparison between Tai & Chyun RDE and existing Chinese RDE

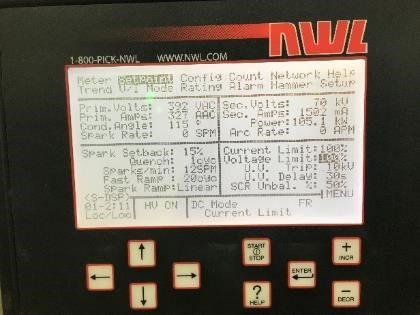

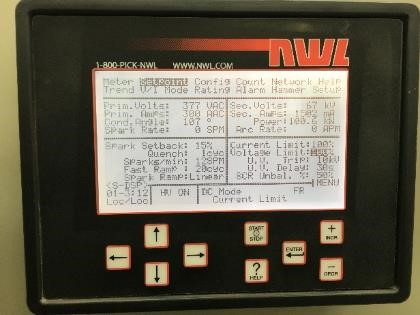

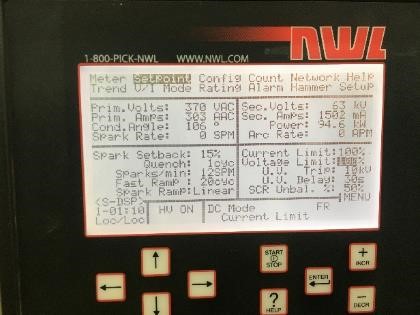

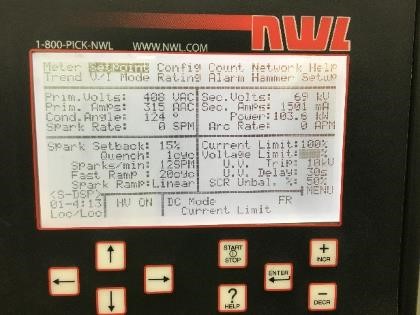

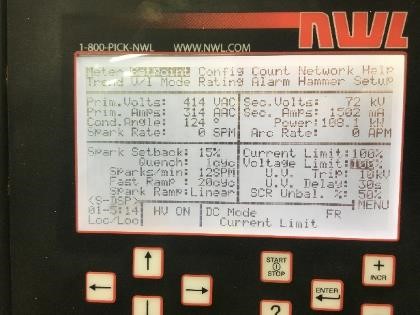

After maintenance activities, static test was conducted and it showed good readings: