KHD DE to Pipe and Spike RDE Retrofit & Collecting Plate Replacement in a Cement Plant

Application

Industry: Cement

ESP OEM / Information: KHD – 1 Chamber (3 Fields)

Process: Cooler

Project Period: November 23 to December 7, 2019

Country: Philippines

Problem

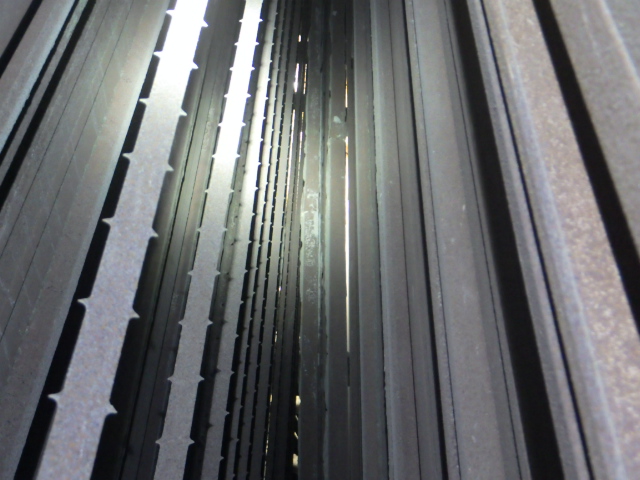

The KHD ESP with original saw band Discharge Electrode (DE) type was experiencing high level of emission. Its DEs were easily broken, bent and possessed several issues resulting in sparking / arcing.

Solution

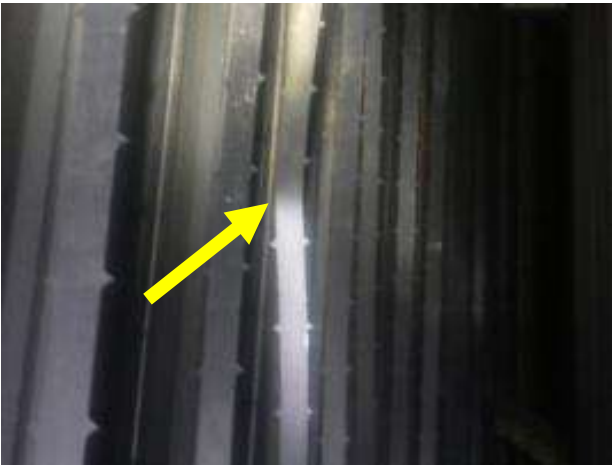

Tai & Chyun recommended replacement of their existing DE (saw band) to Pipe and Spike Rigid Discharge Electrode (RDE) in order to increase collecting efficiency and maintain reliability of ESP operation. We supplied 360 pieces of Pipe and Spike RDE for replacement in 2nd and 3rd field.

As for Collecting Plate (CP), the improvement was done on the thickness that increased from 1.2 mm to 1.5 mm. The entire project of RDE and CP replacement for the 2 fields took 16 days to complete.

Benefit

Tai & Chyun’s Pipe and Spike type Rigid Discharge Electrode (RDE) showed improvement to the overall performance of the ESP.

The advantages of Pipe and Spike RDE are listed below:

- Superior corona generating ability

- Reducing the impact from oscillation

- Bent-proof design

- Higher efficiency and increased reliability during ESP operation

- Stiffness and stability for best rapping efficiency and cleaning effect

- Ease of installation

- Shorter downtime during DE modification

Original KHD Discharge Electrode

Installation of new Pipe and Spike Rigid Discharge Electrode

Newly installed Pipe and Spike RDE at 2nd and 3rd field

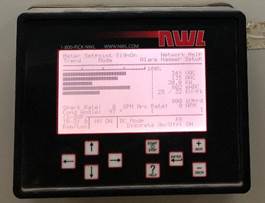

Upon installation of new CP and modified DE (Pipe and Spike) at 2nd and 3rd field, it had been observed that neither sparking nor arcing was detected during the static test.