ESP Rehabilitation at Pulp & Paper Plant in Indonesia

Application

Industry: Pulp & Paper

ESP OEM: SF-Cleanair Oy

Process: 120-ton Power Boiler

Country: Sumatera Selatan, Indonesia

Problem

The ESP is single-chambered with 3 mechanical fields and 22 gas passages, located behind a 120-ton power boiler and has been in operation since 1998. Its dust collection performance had degraded over the years due to aging internal parts and moisture leakage. Severely corroded Discharge Electrode (DE) & Collecting Electrode (CE) and detached rapping bar were found during inspection. These findings led to constant trips in the 2nd field and low mA in the 1st field (approximately only 10% of the rated value). The poor condition of the ESP caused high emission and visible smoke at the stack.

Solution

Replacement of CE, DE and rapping system in the 1st and 2nd fields as well as repair / maintenance in the 3rd field were conducted in early 2021. Before shutdown, a specially built hanging fixture was erected to accommodate the pre-assembled DE with DE frame and CE with suspension beam in order to minimize the installation time.

With comprehensively planned installation procedures, engineers and contractors worked 24/7 and utilized 2 cranes for parallel installation job in the 1st and 2nd field. The installation was successfully completed within 10 days per customer’s expectation.

CE/DE hanging fixture

Penetrant test for new manhole

New CE & DE being installed

Parellel job being conducted by 2 cranes in the 1st & 2nd field

Benefit

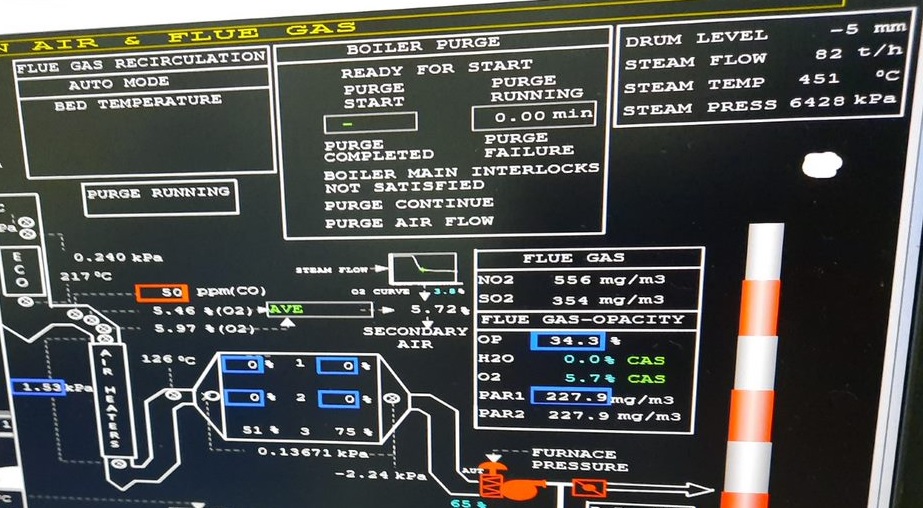

The ESP outlet emission was originally designed at 150mg/Nm3. Before rehabilitation, the running data and stack emission were recorded. The 1st and 2nd fields were already tripped and stack emission was at 227mg/Nm3 with boiler loading of 82 tons/hr, which obviously exceeded the designed value, as shown on CCR display.

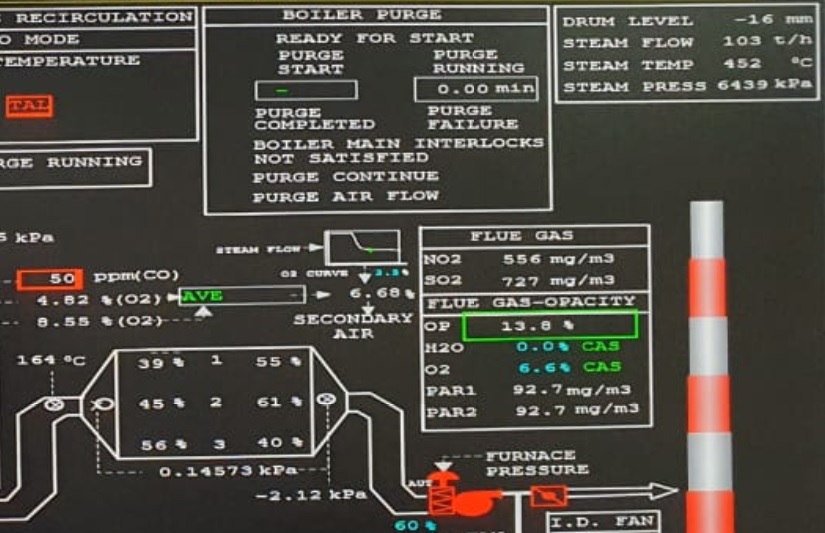

After rehabilitation and rapping frequency optimization, stack emission was lowered to 92mg/Nm3 with even higher boiler loading of 103 tons/hr. The running condition has also improved significantly. Customer was satisfied with the results and has planned for rehabilitation of the 3rd field in the coming shutdown.

| Running Data | Before Rehabilitation | After Rehabilitation |

| Boiler Loading | 82 tons/hr | 103 tons/hr |

| Field 1 kV | Tripped | 39kV |

| Field 1 mA | Tripped | 550mA |

| Field 2 kV | Tripped | 45kV |

| Field 2 mA | Tripped | 610mA |

| Field 3 kV | 51kV | 56kv |

| Field 3 mA | 750mA | 400mA |

| Stack Emission | 227mg/Nm3 | 92mg/Nm3 |

CCR Display

Before Rehabilitation (227.9mg/Nm3)

After Rehabilitation (92.7mg/Nm3)