ESP Inspection & Minor Maintenance in Biomass Plant

Application

Industry: Biomass

ESP OEM: Hamon Cottrell

Fuel: Woodchip

Country: Thailand

Problem

The biomass plant is located in the southern part of Thailand whose electricity generation capacity from woodchip is 9.9 MW. The ESP has been continuously running since 2016. The plant conducted self-inspection and maintenance of the ESP. Not only did they discover sparking when raining, but also dust built-up and bent internal parts. In order to determine an appropriate solution in maintaining ESP efficiency, thorough inspection and proper maintenance were highly recommended.

Solution

Tai & Chyun conducted thorough ESP inspection on mechanical parts such as Collecting Electrode (CE), Discharge Electrode (DE), Gas Distribution (GD) Screen, Baffle Plate, and Insulators as well as minor maintenance for 3 fields during the outage. Minor maintenance work was carried out according to the problems found during inspection. Electrical tests like resistance and insulation test were also done to ensure both mechanical and electrical parts were in good conditions.

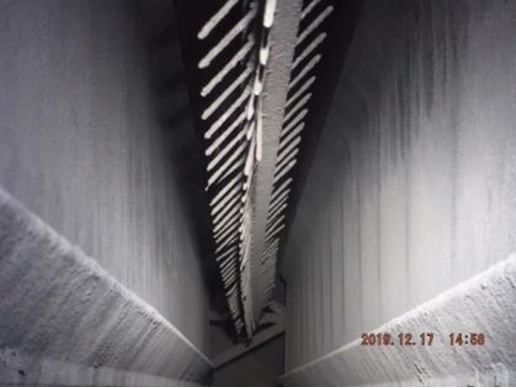

Bent and twisted DEs were observed in several rows and some were severely bent causing gap between DE and CE to be less than standard requirements. Those were removed in order to prevent arcing during operation. Broken and torn MIGI Rapper’s rubber boot seals were renewed and tightened to prevent moisture from entering the penthouse and causing cracks to the insulators. Burnt insulator rods as a result of moisture leakage were also found and replaced.

In addition, tightness of bolt & nut and re-weld were checked. Loosened bolt and nut could cause internal parts to move that may lead to sparks and trips. The entire work was completed within 3 days and recommendation for maintenance work scope in the next outage had been provided.

Bent DE

Loose bolt and nut

Twisted DE

Torn rubber boot seal

Burnt insulator rod

Benefit

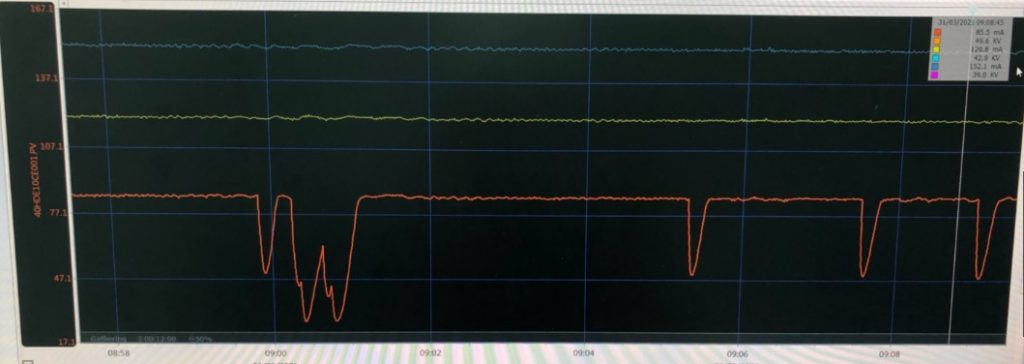

After inspection and minor maintenance, less spark occurrences mean ESP operation has become more stable and reliable and thus increase in ESP’s efficiency. Comprehensive ESP inspection report provided by Tai & Chyun also helped the plant in planning future maintenance work and spare parts more efficiently.

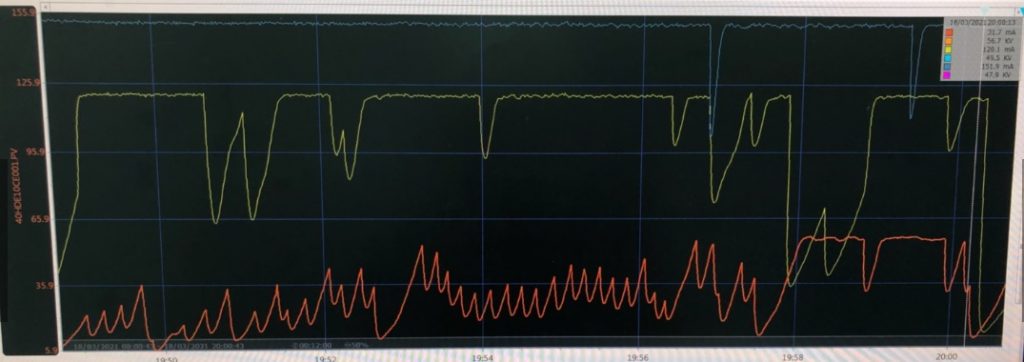

Spark rate before maintenance

Spark rate after maintenance