Collecting Electrode & Discharge Electrode Retrofit in a Cement Plant

Application

Industry: Cement

Capacity: 1,600TPD

ESP OEM / Information:

OEM: Korea Cottrell

Process: Raw Mill / Kiln

Start of Operation: 1995

Original Type of Electrodes: CE (Sword type), DE (Dura-Trode)

Rapping Design: MIGI Rapper for both CE and DE

Country: Philippines

Problem

Past inspections in the Kiln ESP revealed a major issue as the unit showed signs of aging parts. Collecting Electrode (CE) and Discharge Electrode (DE) systems had started to deteriorate resulting in poor collecting efficiency. Furthermore, such CE and DE designs were obsolete and not anymore available in the market.

Solution

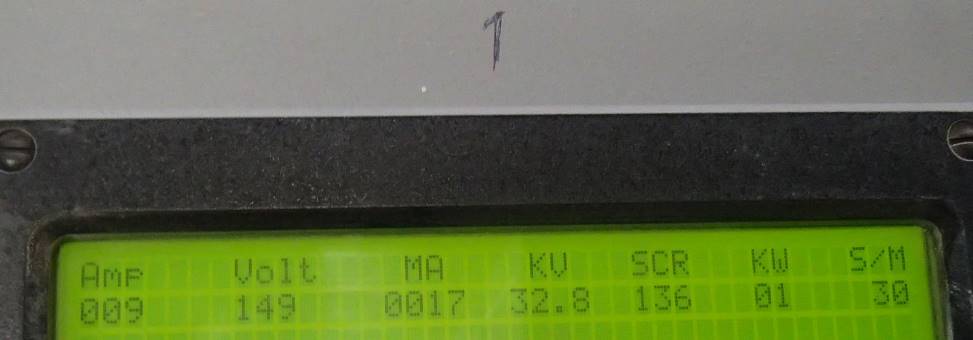

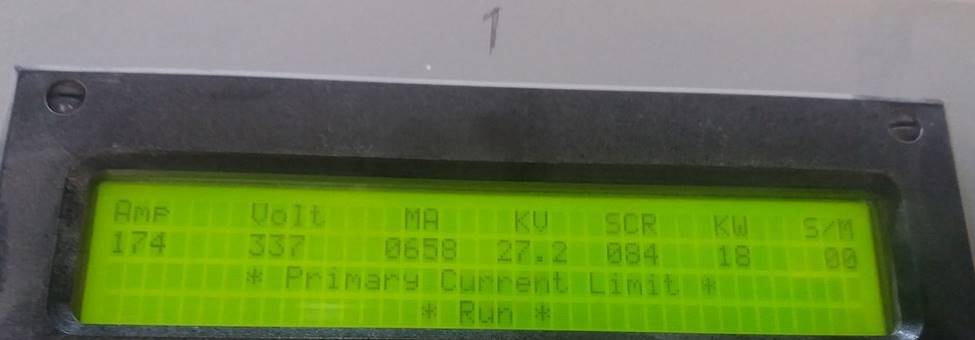

Due to design obsolescence, Tai & Chyun proposed to retrofit Dura-Trode DE to Pipe and Spike type and CE to a more improved design. Pipe and Spike DE design provides more aggressive corona current generation particularly at high dust loading. The installation was carried out at the inlet field to handle the heavier dust load.

New design of CE and DE

Benefit

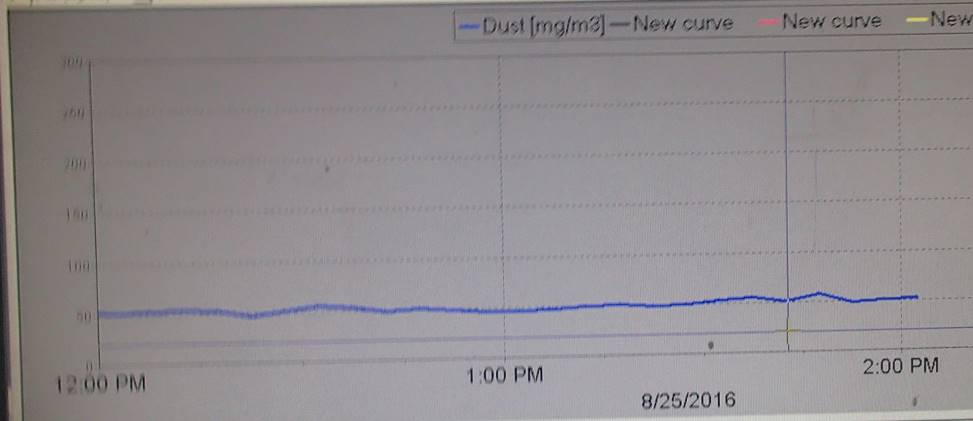

The retrofit to Rigid DE and new CE design allowed the ESP to operate reliably thus preventing emergent or unnecessary shutdowns due to broken / damaged internal parts. Such retrofit also helped the plant keep their emission level below regulation limits and so continuous smooth production could be achieved.