Ash Handling System Maintenance in a Power Plant

Application

Annual maintenance of an 800-MW ultra-supercritical coal-fired unit of a power plant in Taiwan.

Problem

Huge amount of ash being generated is a common problem in such a large-scale coal-fired power plant. Since it shares the ash silo with other equipment, it is important to maintain its system making sure that the function works properly to lower the risk of failure and facilitate long-time operation.

Solution

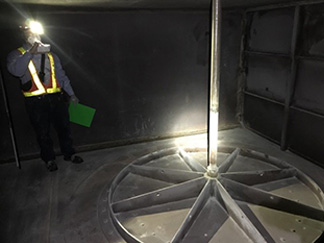

Tai & Chyun performed inspection and maintenance services on the scope of ECO, SCR, APH, PRS, and Ash Silo that include some main parts such as Dampers, Valves, Drivers, Transport Pipes, Ash Silos, and Hoppers.

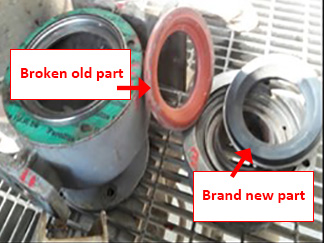

Conditions of all parts were inspected and actions were taken. For example, lubrication was applied to the damper bearing to make sure that the inlet opens and closes smoothly, valve seat and disc were checked for any worn out and safe gap, broken O-ring cover and gasket from the damper and valve drivers were replaced and tested for any leakage.

Benefit

There are many benefits to having a preventative maintenance program in place for your Ash Handling System. It lessens the possibility of equipment failure, reduces downtime and repair costs, improves productivity, and prevents unexpected or urgent shut down for a repair.

Photo