ESP Mechanical Replacement and Controller Retrofit in Power Plant

Application

Industry: Power

Capacity: 3 units x 10 Megawatts

ESP OEM / Information: Chinese

Process: Power Boiler

Country: South East Sulawesi, Indonesia

Problem

The plant’s ESPs have been operating since 2012 when ESP Unit 1 exploded with unclear reason in May 2016 while it was running for approximately 5 – 6 months after its last shutdown. All the internal parts in Field 1 and Field 2 were severly damaged due to the explosion, while Field 3 was barely working at very low value around 50kV / 120mA collecting dust. Another problem of this ESP was its existing controllers were obsolete, therefore, it was difficult to acquire spare parts. Furthermore, the readings between analog meter and digital display were discrepant.

Solution

The plant decided to do mechanical replacement for the entire Field 1 and Field 2. The project had been awarded to Tai & Chyun for supplying mechanical parts and providing supervision of installation service. Mechanical parts supplied by Tai & Chyun were Collecting Plate (CP) & Rapping System, Discharge Electrode (DE) & Rapping System, and Insulators.

On electrical side, the plant decided to replace the existing Chinese controller with Graphic Voltage Controller (GVC) to experience the latest technology of Automatic Voltage Control (AVC) in order to gain better control of ESP parameters. The project was executed from October to November 2017 with successful results despite some issue occurrences such as lack of tools and manpower from the plant.

Newly installed Rigid Discharge Electrode (RDE)

Newly installed rapping insulator

Newly installed CP (top)

Newly installed CP Rapping System

Newly installed GVC

Newly installed CP (bottom)

Benefit

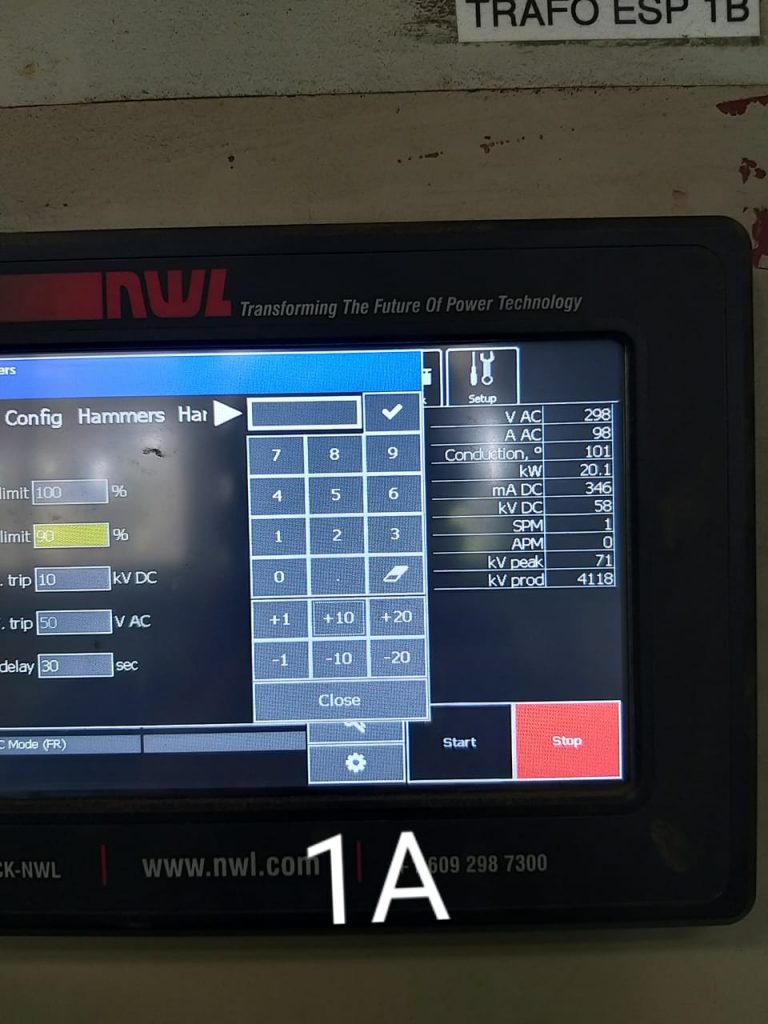

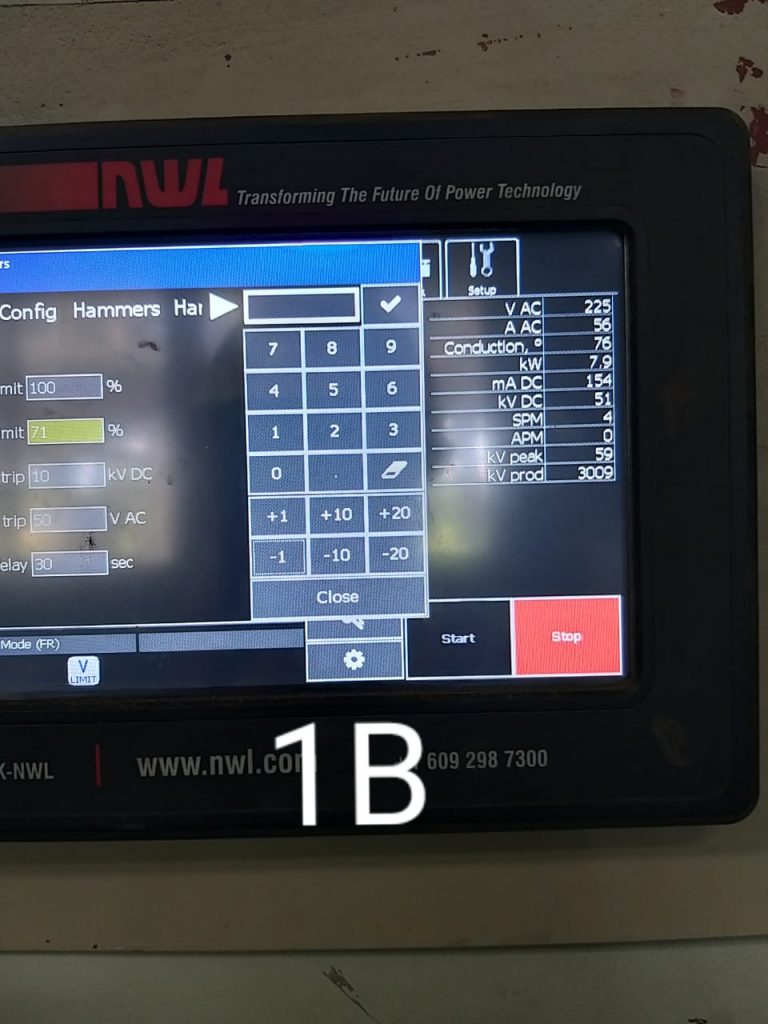

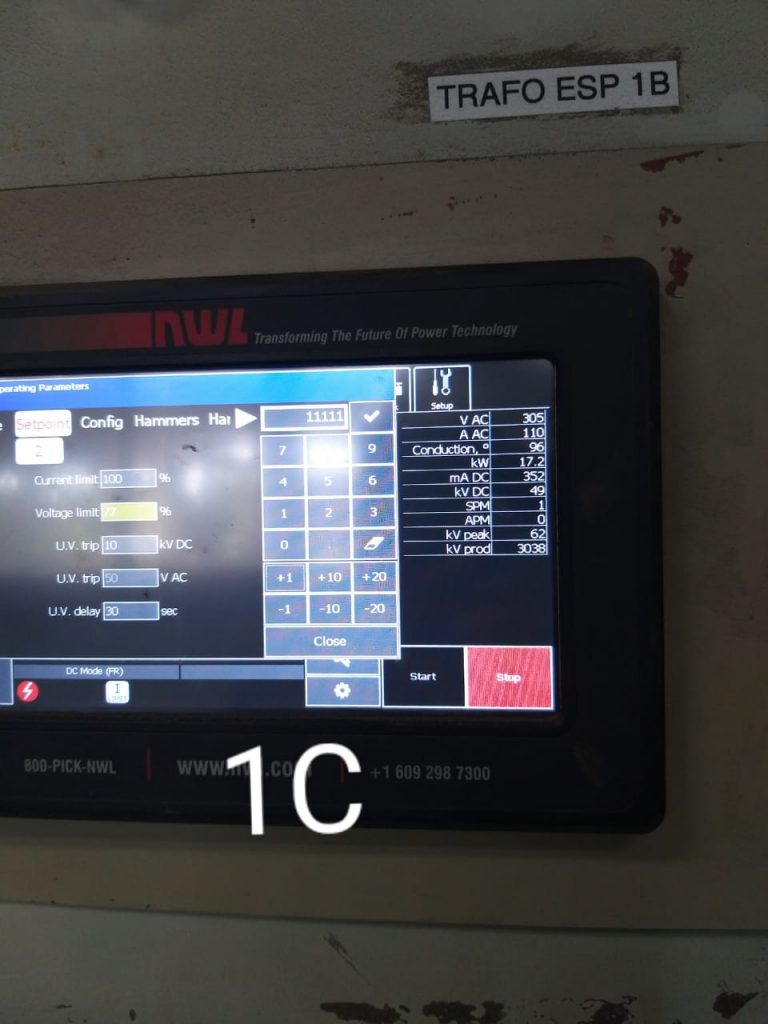

Good results were shown after project completion as customer expectation had been met that ESP was back to operating well after the explosion. ESP running parameters were checked by doing no-load test, which proved that mechanical parts were in good condition. In fact, both mechanical and electrical checks showed even better results compared to the other ESP units. Readings data after 2-year operation shows that the ESP is still in good condition as below.

58kV / 346mA

51kV / 154mA

49kV / 352mA

Note:

*) T/R Rating: 380V / 110A; 72kV / 400mA

**) One (1) keypad to control three (3) T/Rs