Application

25.4 MW Power Boiler ESP at Pulp & Paper plant in Thailand.

Problem

Customer originally has very high emission at 229 mg/m3. Therefore, it is compulsory for them to take some action towards ESP in order to solve emission problem.

Solution

It is recommended by Tai & Chyun to perform ESP upgrade through an adoption of high frequency transformer as it is considered to be one of the most optimal solutions that can remarkably help to bring down emission.

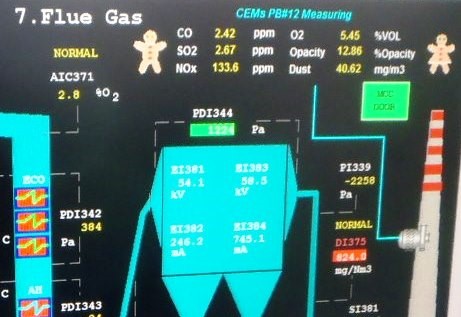

Accordingly, 2 units of high frequency transformers were installed in both 1st and 2nd field of ESP, where one ESP consists of two fields in total.

Benefit

High frequency transformer is proven to provide better power factor. It operates at higher frequencies (in cycles/sec), while it can translate to smaller transformers and faster control responses. With its lower ripple, it is applicable to achieve much higher average voltages (kVDC) for a given peak kV, leading to an improvement in the ESP collecting efficiency and reduction in emission.

After an installation, emission can be reduced from 229 mg/m3 down to 40.62 mg/m3, which shows a significant improvement.