Application

Smelting Plant in Indonesia.

Problem

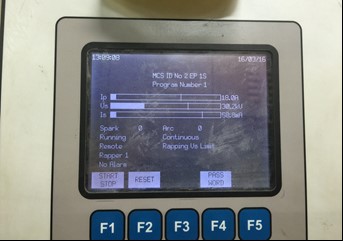

- Old controller show unreliable operating data. To illustrate, one out of 2 fields the operating data showed maximum mA value followed by high number of sparking.

- High number of sparking and suspected back corona phenomena

- Higher outlet particle concentration than design data

- Obsolete TR and Controller

Solution

PowerPlusTM technologies were recommended to install for replacing existing conventional T/R set. Tai & Chyun was awarded the contract to supply two units PowerPlus of 83kV_1155mA, installed onto 1st field of two units of dry ESP ( Converting-ESP & Sintering-ESP), together with the control panel renewal.

Benefit

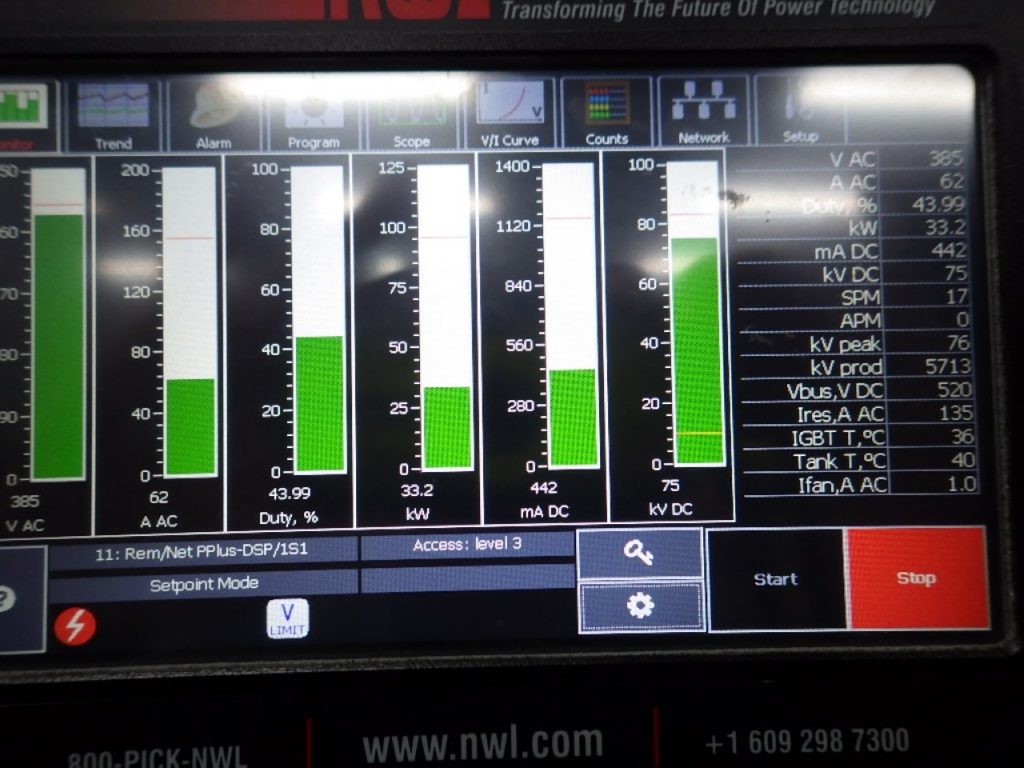

After installation, PowerPlus could give more reliable and stable data. They also provide a clearly displayed and can automatically recorded ESP data during operation.

Due to theirs circuit components and function, PowerPlus unit delivered more power into the ESP, providing less kVA per kW output, and higher kV compared with conventional T/R set. It produced a near peak voltage output with low ripple.

Moreover, after upgrading ESP with PowerPlus, the operating data showed significant improvement on the kV and mA with less spark per minute. Since the PowerPlus uses IGBT system and operates at high frequency, it can sense an arcing and shutdown in as quickly as 30 microseconds. As a result, it can adapt rapidly to changing conditions due to their digital signal processor (DSP). Therefore, it can be clearly observed that PowerPlus could dramatically enhance the current and the power level.

The table below shows the current and power level enhancement after PowerPlus upgrading.

| ESP | Converting-ESP | Sintering- ESP | |

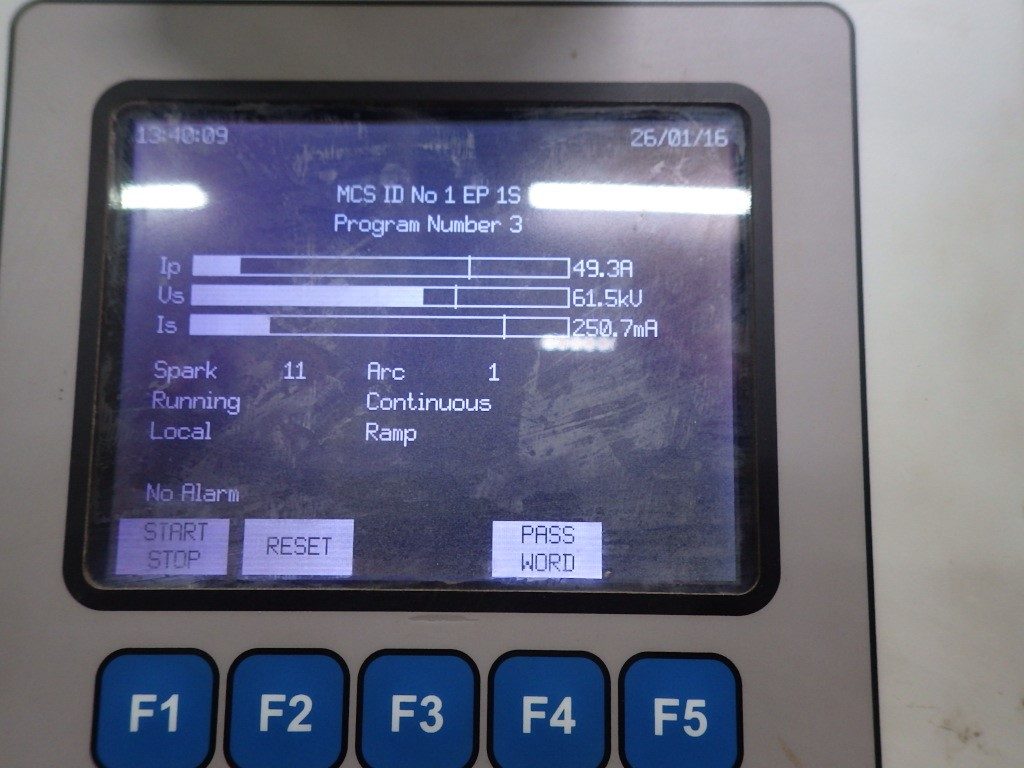

| Conventional T/R set | kV | 30.2 | 61.5 |

| mA | 58.8 | 250.7 | |

| Power Plus | kV | 53 | 75 |

| mA | 582 | 442 |

Accordingly, higher power given into the ESP is proportional to the ESP performance and collecting efficiency. PowerPlus retrofit will help increase collecting efficiency.