Application

Raw Mill Cement ESP in Vietnam.

Problem

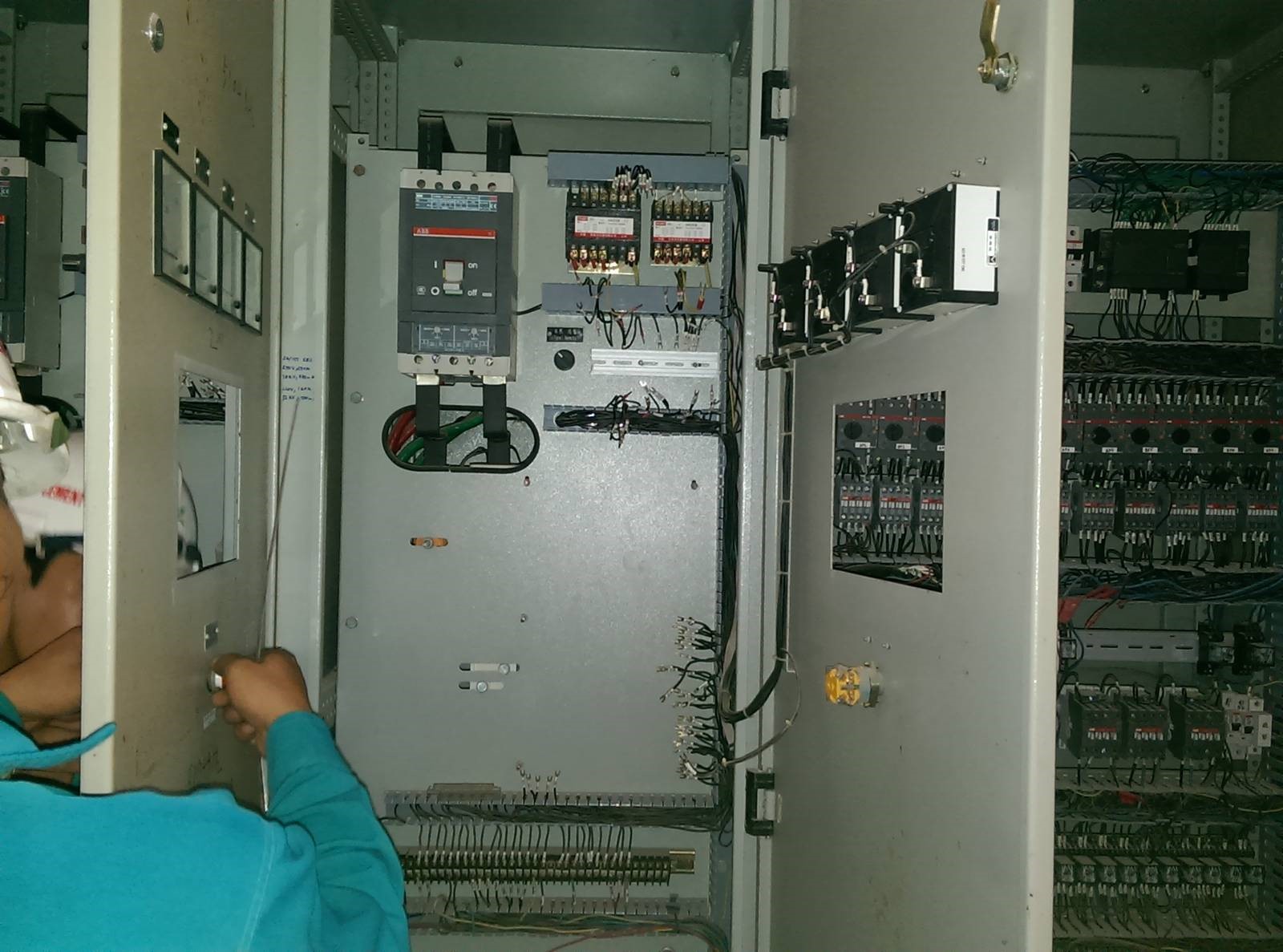

This cement plant was started up in July, 2008. They use Chinese ESP with the use of Chinese controller as well. Their ESP has some mechanical and electrical problems. Most of their controller was malfunctioned and unreliable to display correct performance. Regarding to this, Tai & Chyun advised that they should do controller retrofit to be able to obtain more reliable reading in order to have a better awareness of ESP condition.

Solution

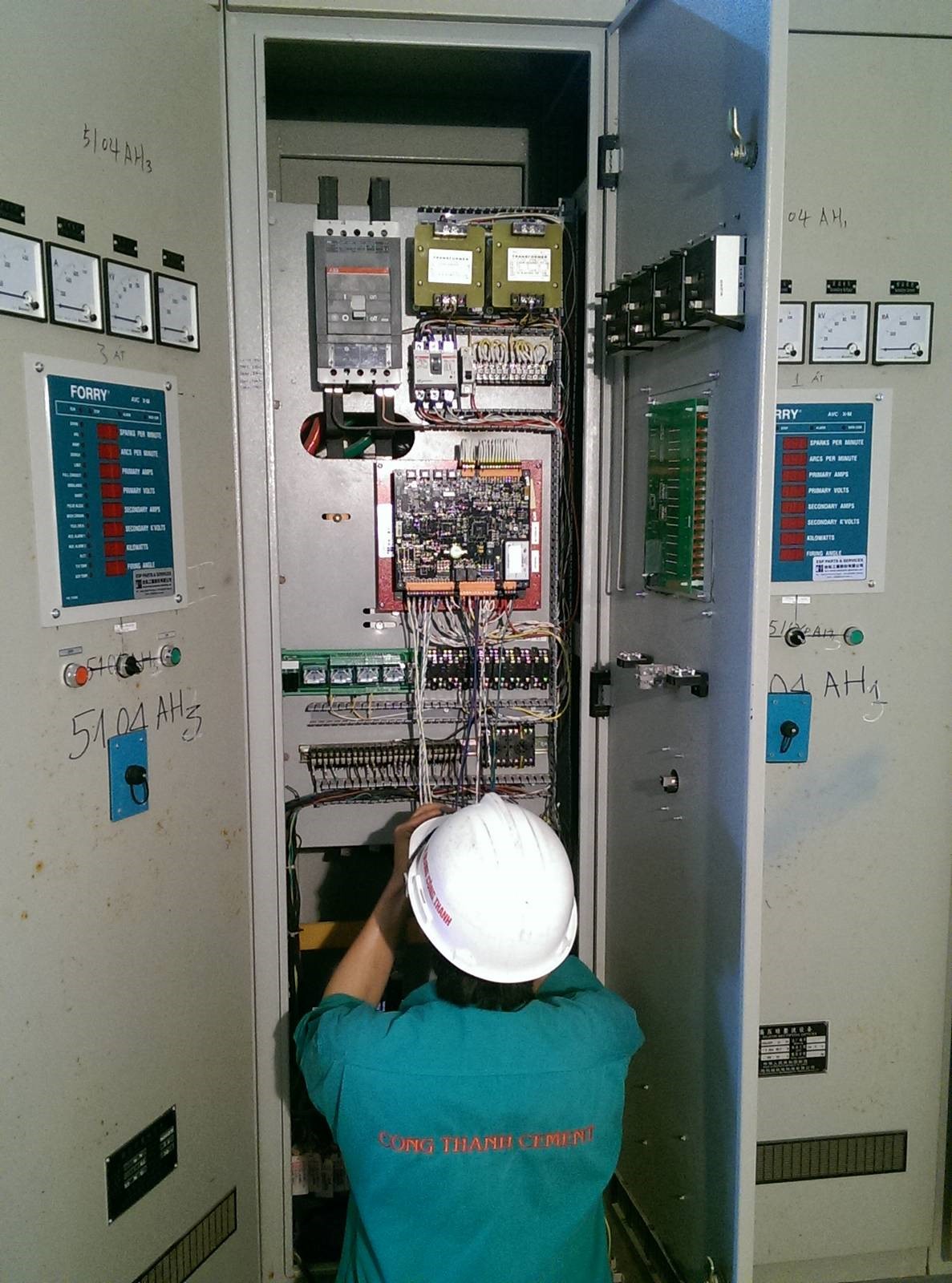

Customer was impressed that Tai & Chyun was the first ESP solution provider who sincerely helps solving their ESP problems and frequently visits and follows up with them, while it is hard for them to contact Chinese ESP OEM once after the ESP installation work finished. They always have a confidence in Tai & Chyun. Thereby, they awarded us to supply three new units of controllers, together with installation supervision in raw mill ESP. Moreover, Tai & Chyun also provided training class to teach them how to use controller, to read operational data and adjust controller setting in order to make sure that customer will be able to use controller properly.

Benefit

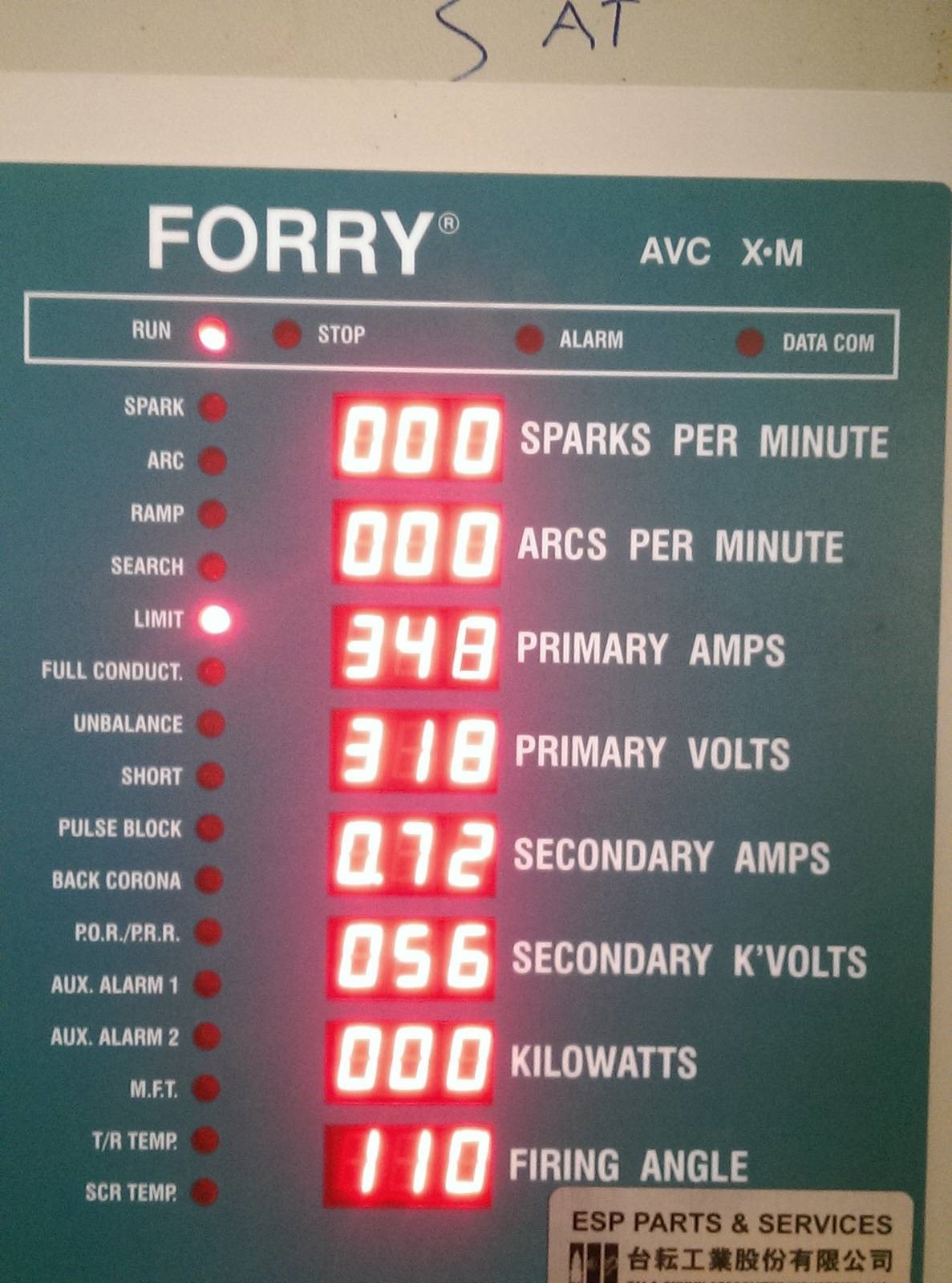

With Tai & Chyun’s visit to follow up after the controllers were retrofitted, customer was satisfied with the quality of the new controllers. It is observable that the new controllers can now show reliable readings. Also, with new controller, it helps improve the power supply into ESP as it can be seen from an increase in the operating data after controller retrofit as shown below. With the new controller, it will help user to increase dust collecting efficiency by optimizing the voltage delivered to the ESP under varying load condition.

| Field No. | Before Controller Retrofit | After Controller Retrofit | ||

| kV | mA | kV | mA | |

| Field 1 | 40 | 200 | 56 | 710 |

| Field 2 | 50 | 300 | 55 | 680 |

| Field 3 | 20 | 400 | 52 | 510 |