Application

Cooler ESP of a cement plant located in Cambodia.

Problem

- Unstable operation of controller

- Worn out mechanical parts & misalignment problem

- Worn out original top rapping system, including loose connection, and broken shaft

Solution

The overhaul maintenance & modification works were carried out within 12 days working 2 shifts / 24 hours:

- Design & modification of DE rapping system from top rapping to side rapping

- Supply of new DE frame & installation supervision

- GVC controller installation

- Supply of minor parts such as CP hammer, insulator, etc.

- Installation of walkway

Limitations & difficulties encountered during maintenance:

- Modification work: Due to the alignment of H beam and rapping shaft, the rapping insulator box with dust removal screw could not be installed directly.

Solution: Minor modification of H beams and DE rapping shaft location was carried out.

- Electrical: 1 keypad to control 3 mainboards.

Solution: Use networking connection and apply on/off push button to control the ESP in case the keypad faces malfunctioning problem.

Benefits

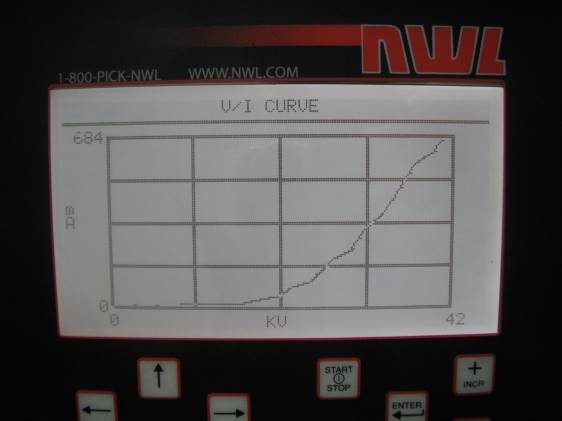

No load test was carried out after installation. ESP was operating efficiently with stable performance.

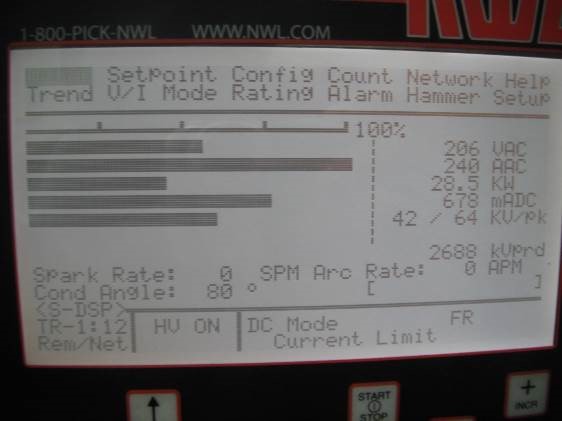

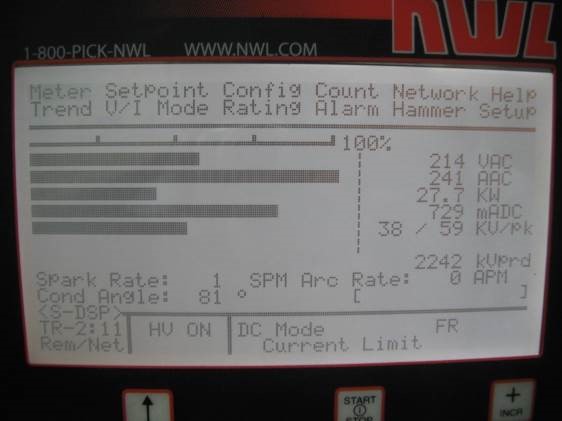

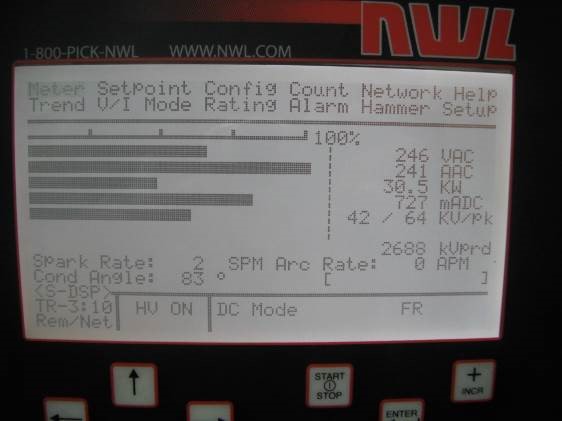

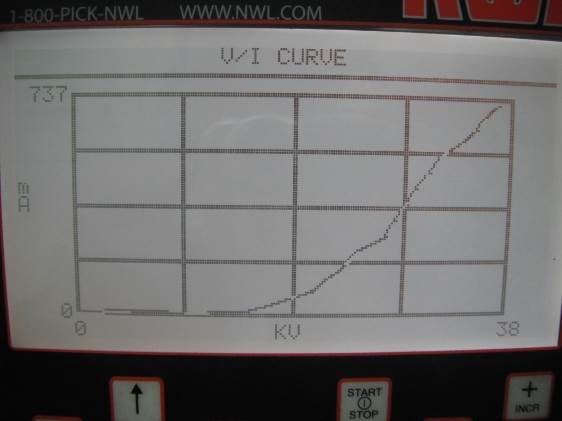

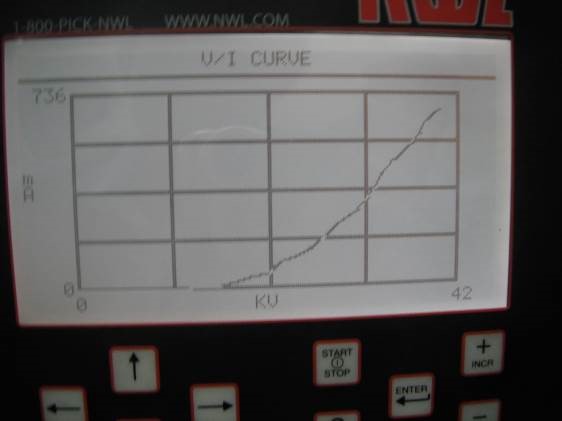

| Field Number | Before (Load Test) | After (No-Load Test) |

| Field 1 | 0kV/146mA (swing kV) | 42kV/678mA |

| Field 2 | 36kV/541mA | 38kV/729mA |

| Field 3 | 55kV/467mA | 42kV/727mA |