Application

Biomass power boiler ESP of an Indonesian Pulp and Paper Factory.

Problem

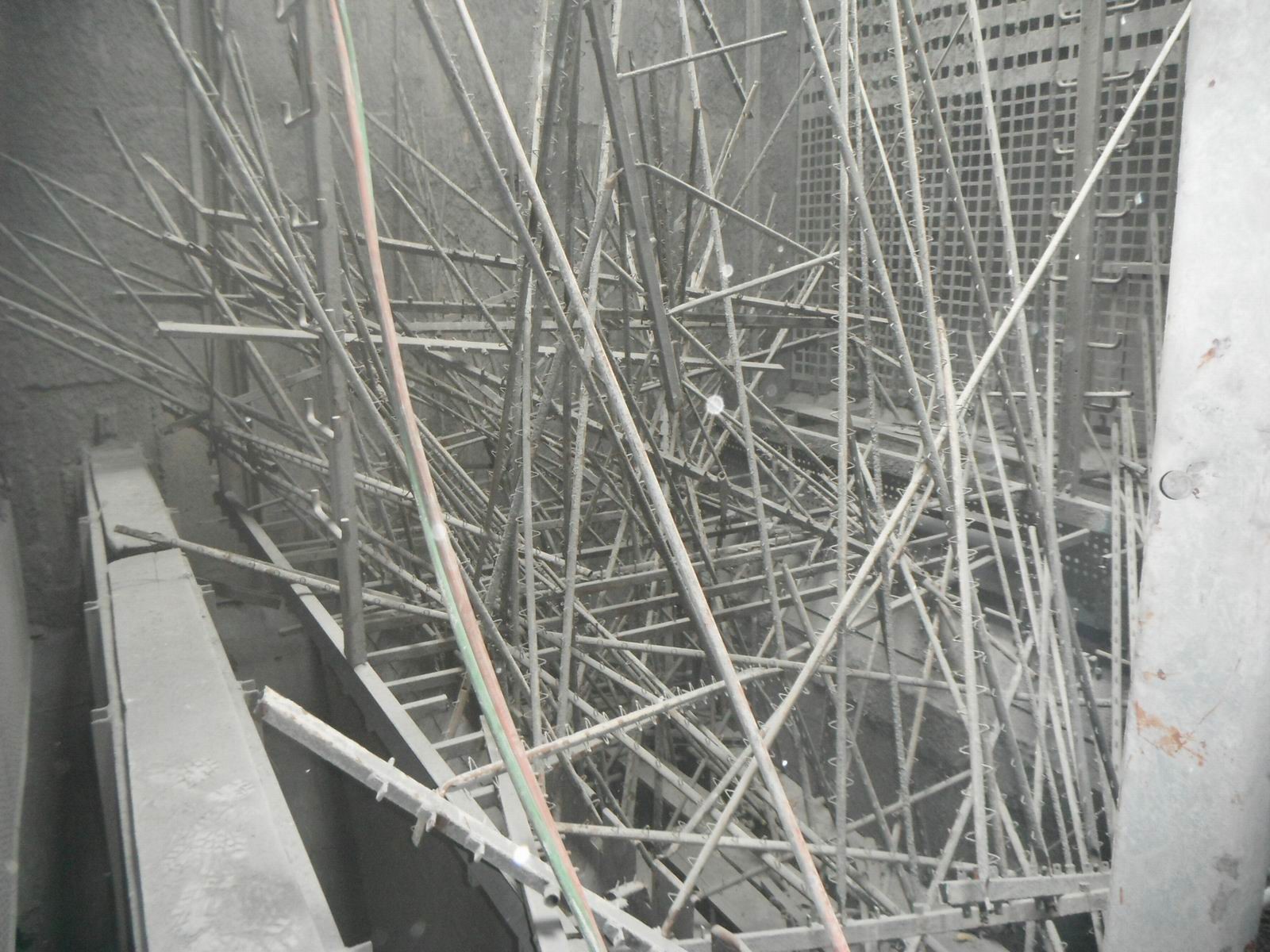

The ESP has been in operation for more than 25 years, and the following problems were found:

- Heavy dust buildup on CP and DE

- Heavily corroded CP and DE

- Missing DE’s

- Severe abrasion of CP and DE rapping shaft

- Worn out pinwheel (DE rapping drive)

- Black smoke coming out from the chimney

Solution

Tai & Chyun recommended the renewal of DE from old type DE to new type DE in order to improve the performance and reliability of the ESP. During this shutdown, only the second field of both the ESP was renewed.

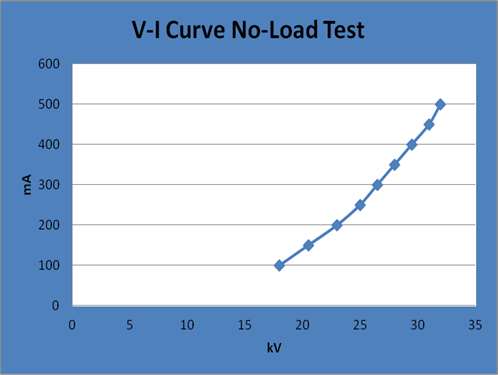

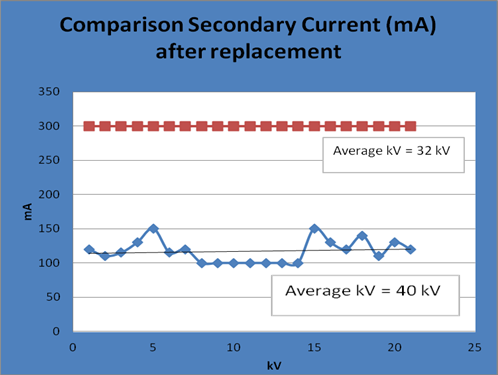

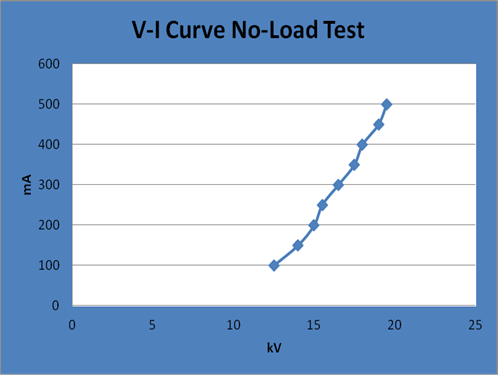

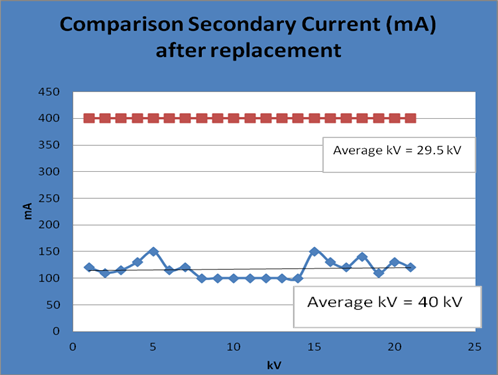

After improvement, the full-load operating values of the two ESP were as follows:

| ESP | kV | mA |

| 1 | 32 | 300 |

| 2 | 29.5 | 400 |

The ESP was running efficiently with stable mA.